Technologies for resource-efficient electronic systems

Increasingly complex requirements are being placed on the environmental compatibility of electronic systems. In the past, the main considerations were energy conservation, some heavy metals in the assembly, and certain flame retardants. Today the environmental discussion is focussed on critical resources (e.g. rare earth metals and conflict materials) in view of foreseeable supply bottlenecks and the environmental impact of mining, as well as on halogenated flame retardants.

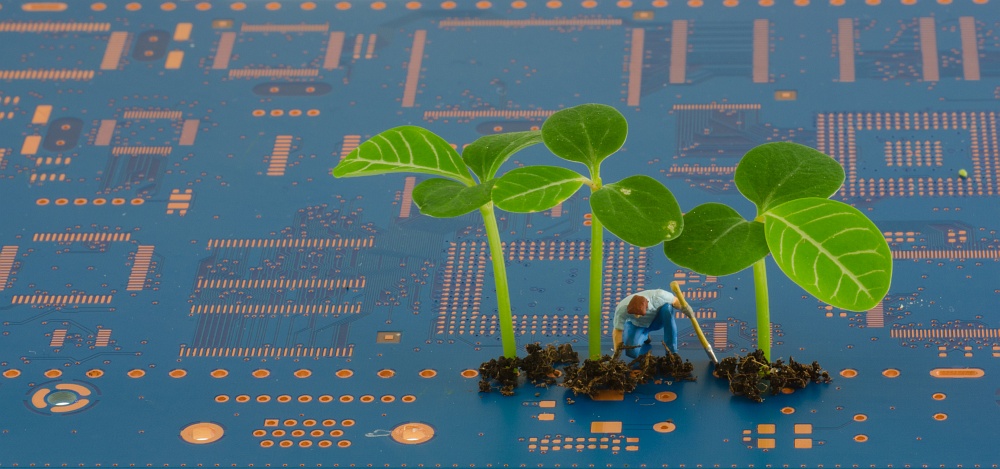

The demands for increased resource efficiency present special challenges for technology developers in times of depleted resources and rising prices. One possibility is the use of bio-based polymers for casings and printed circuit boards in order to conserve fossil resources: The new materials must meet the high technical requirements for uses in electronics, should not have a worse environmental impactthan fossil-based plastics, and must be available for processing at acceptable costs.

The goal of the research is the more efficient use of fossil fuels, metals and other resources by means of innovation in the production processes, during use, and/or at the end of the life-cycle (including recycling). Technology development can be approached at various levels: Electronic components, individual products or groups of devices, such as LED products. The complex interactions and interfaces require a systemic approach and thinking outside the box.

Technologies for resource efficient electronic systems concentrate on:

- Solutions for the efficient use of resources by means of substitution, increased reliability, longer durability and design for recycling

- Evaluation and comparison of technologies and materials in terms of resource efficiency

- Minimising the environmental impact of processes in packaging and interconnection technology

Estimation of the environmental impact of subsequent commercialproduction (Lab to Fab)

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM