Analytical, numerical and experiment-based assessment of electromigration in electrical contacts

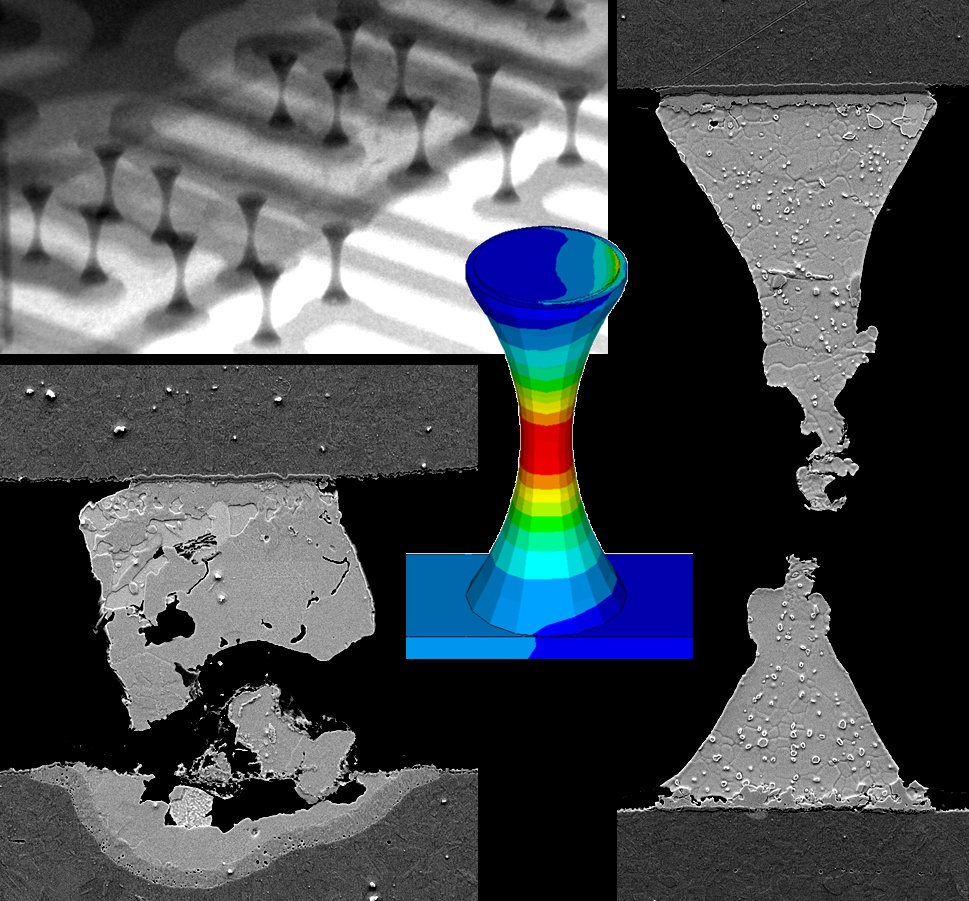

One factor limiting the reliability of increasingly miniaturized electronic systems is failure due to electromigration. This current- and temperature-induced mechanism displaces atoms in the conducting material, leading to defects in the electrical traces and solder joints.

Any investigation of electromigration as part of optimized, model-based evaluation has to take into account the effects of interdependent parameters. Many different types of forces can lead to additional material transport, including surface tension and temperature gradients (surface migration, thermal migration).

We perform the following types of analyses using application-specific experiments:

- Weak-spot analysis (theoretical, experimental)

- Design optimization using finite-element analysis

- Characterization of solders and determination of material properties for lifetime prediction

- Application-specific in-situ monitoring and assessment of on-going degradation

- Development of advanced failure models

Electromigration analysis of electrical interconnections are carried out according to the following norms and testing methods:

- JEDEC JEP154 (2008): Guideline for Characterizing Solder Bump Electromigration under Constant Current and Temperature Stress

- ASTM F1259M-96(2003): Guide for Design of Flat, Straight-Line Test Structures for Detecting Metallization Open-Circuit or Resistance-Increase Failure Due to Electromigration

- ASTM F1260M-96 (2003): Standard Test Method for Estimating Electromigration Median Time-To-Failure and Sigma of Integrated Circuit Metallizations [Metric]

- JEDEC standard JESD87 (2001): Standard Test Structure for Reliability Assessment of AlCu Metallizations with Barrier Materials

- JEDEC standard JESD63 (1998): Standard Method for Calculating the Electromigration Model Parameters for Current Density and Temperature

- EIA/JEDEC standard EIA/JESD61 (1997): Isothermal Electromigration Test Procedure

- IPC standard 9701A (2006): Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM