Berlin

Software tool saves hours in battery production

Since its launch in March 2016, application-oriented research has only been part of the mission of the microbattery line. The internal processes in battery production have also been optimized – with some astonishing results.

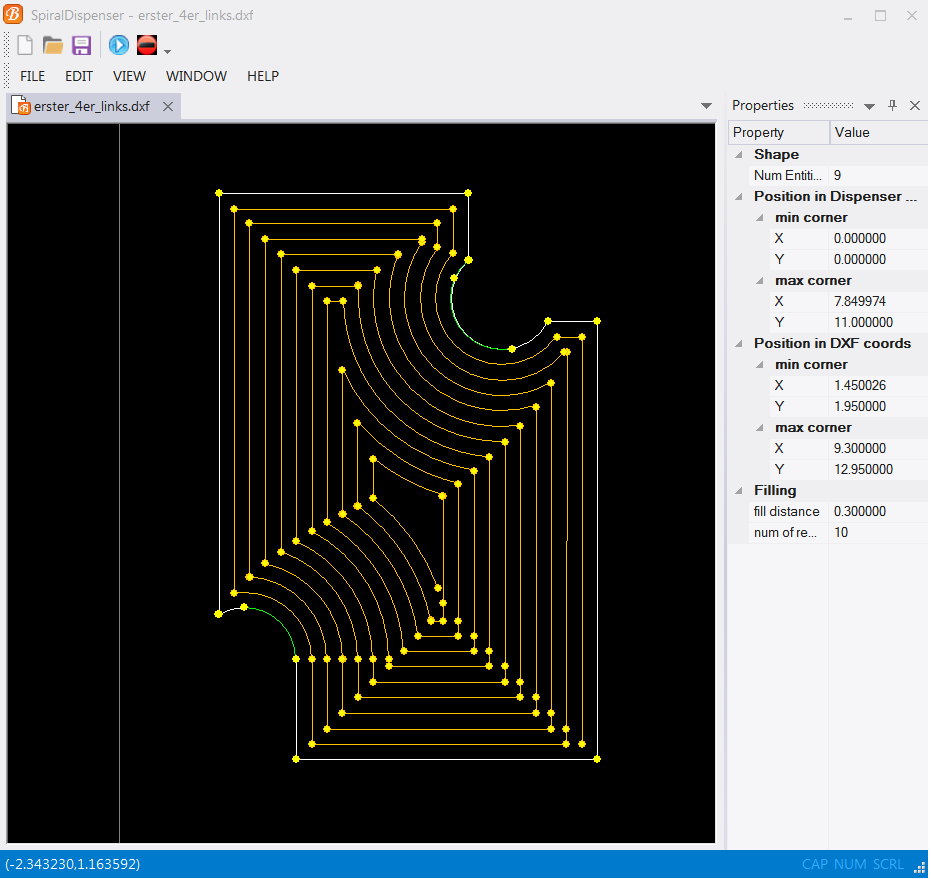

The first instance of this was the EDA tool developed by the Bernd Stube’s software team, which managed to automate the planning of the route used by the dispenser to fill the anode and cathode paste as homogeneously as possible in aluminium or copper substrate cavities. Without it, routing had to be done by hand, in a slow and laborious calculation, for each new form factor – costing up to half a day of effort depending on the shape of the cavity. Since the introduction of the home-grown solution in early 2017, routing can be completed in mere seconds. This not only saves time, but also allows for much more flexible, diverse, and customized designs for future microbattery architectures.

In March 2016, the research group under Robert Hahn took up its research work on the battery development and assembly line, run by the Fraunhofer IZM in cooperation with the Technical University of Berlin. The group has been promoting new developments in the design and production of microbatteries, e.g. to power small and miniature sensors autonomously.

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM