Materials characterization and modeling

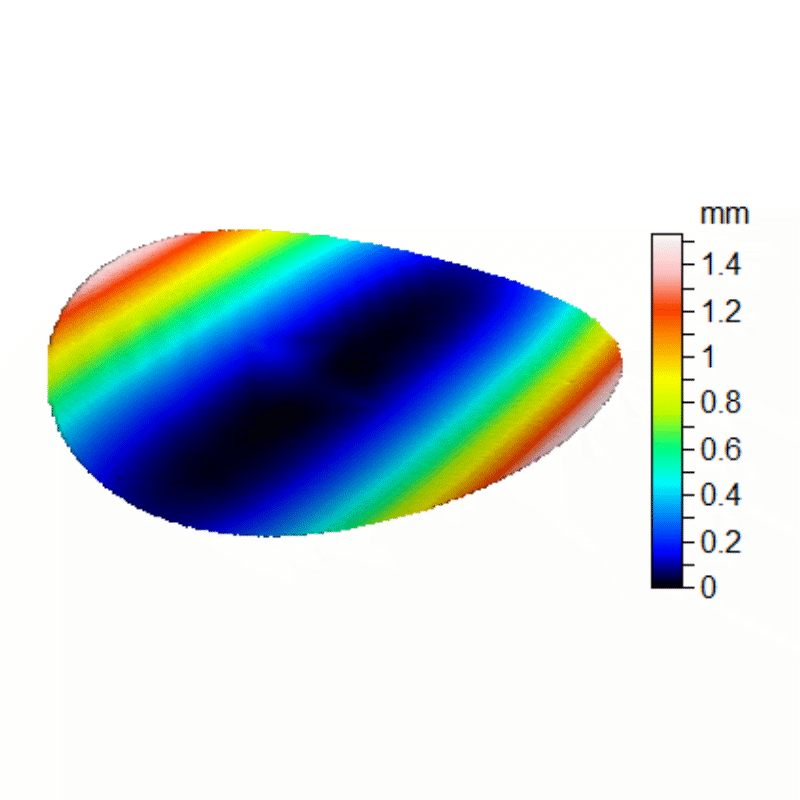

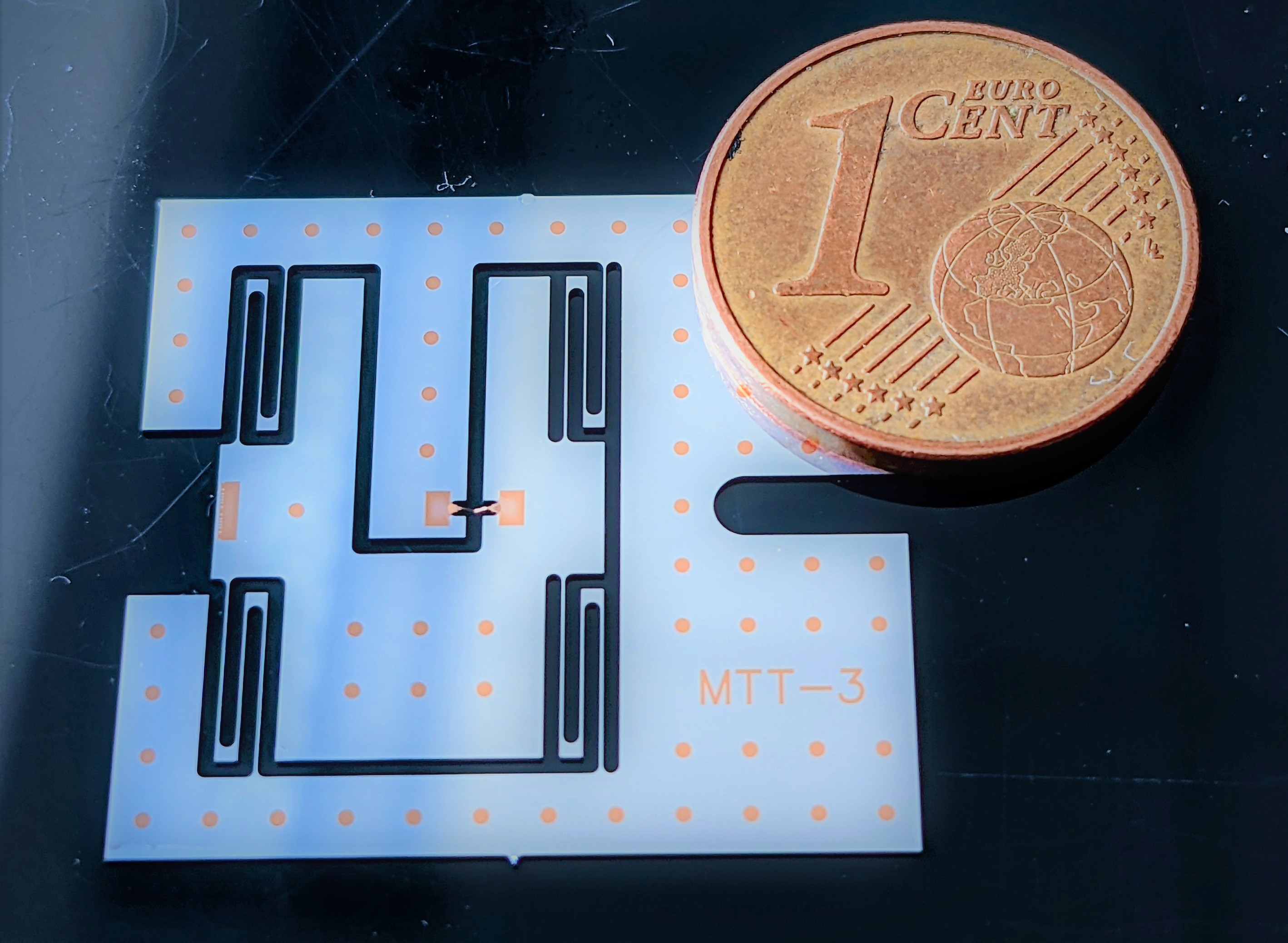

Electronic systems are subjected to numerous environmental influences throughout their working life. Factors such as mechanical forces, temperature fluctuations and exposure to moisture can significantly impair the reliability. In order to optimise the reliability of complex systems in the micro/nano range it is important to understand the development of material failures. In order to be able to describe deformation, damage and fracture in materials, either alone or in combinations, it is necessary to investigate loads under the appropriate conditions. The methods of thermo-mechanical simulation are helpful here as universal tools by providing suitable failure criteria and models for the evaluation of the reliability of real components. It is then possible to draw conclusions about ways of improving their construction.

This topic concentrates on the following:

- Material characterisation and modeling

- Evaluation of reliability at interfaces, new methods of characterisation in the micro-nano transition range

- Material simulation (multi-scale simulation, molecular dynamics)

The experimental results and the combination of the individual methods serve to validate the simulation results with real assemblies.

You can find an overview of our range of services here.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM