Design assessment and optimisation for reliability

Already in the early stages of the design process for a new product, FEM analysis can be used to compare alternatives quickly and to optimise the design in terms of reliability and durability. When selecting suitable technologies for a new product, FEM makes it possible at an early stage to take into account the effects of the production process itself and of use over the operating life of the product.

The emphasis is on thermal and thermo mechanical simulations, in part superimposed with vibrations and purely mechanical stresses. Careful thermal management can result in reliable operations even under increased ambient temperatures. Avoiding excitations at eigen-frequencies is important in order to ensure reliable operations in settings with increased exposure to vibrations.

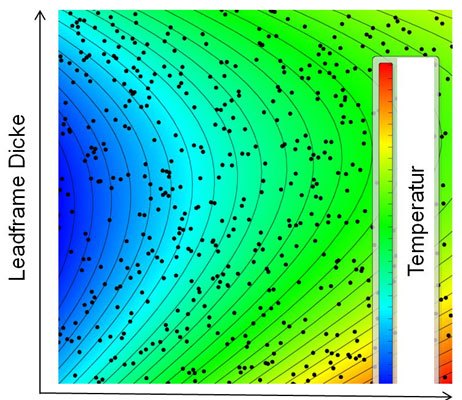

Tools such as OptiSLang make it possible to identify key influences and to optimise the design in terms of a number of factors. Parameters for models and material data can be used in order to compare and evaluate many options quickly and cost-effectively. Even in short development phases it is then possible to develop product technologies which are efficient in terms of function, environmental conditions, size, weight and reliability requirements.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM