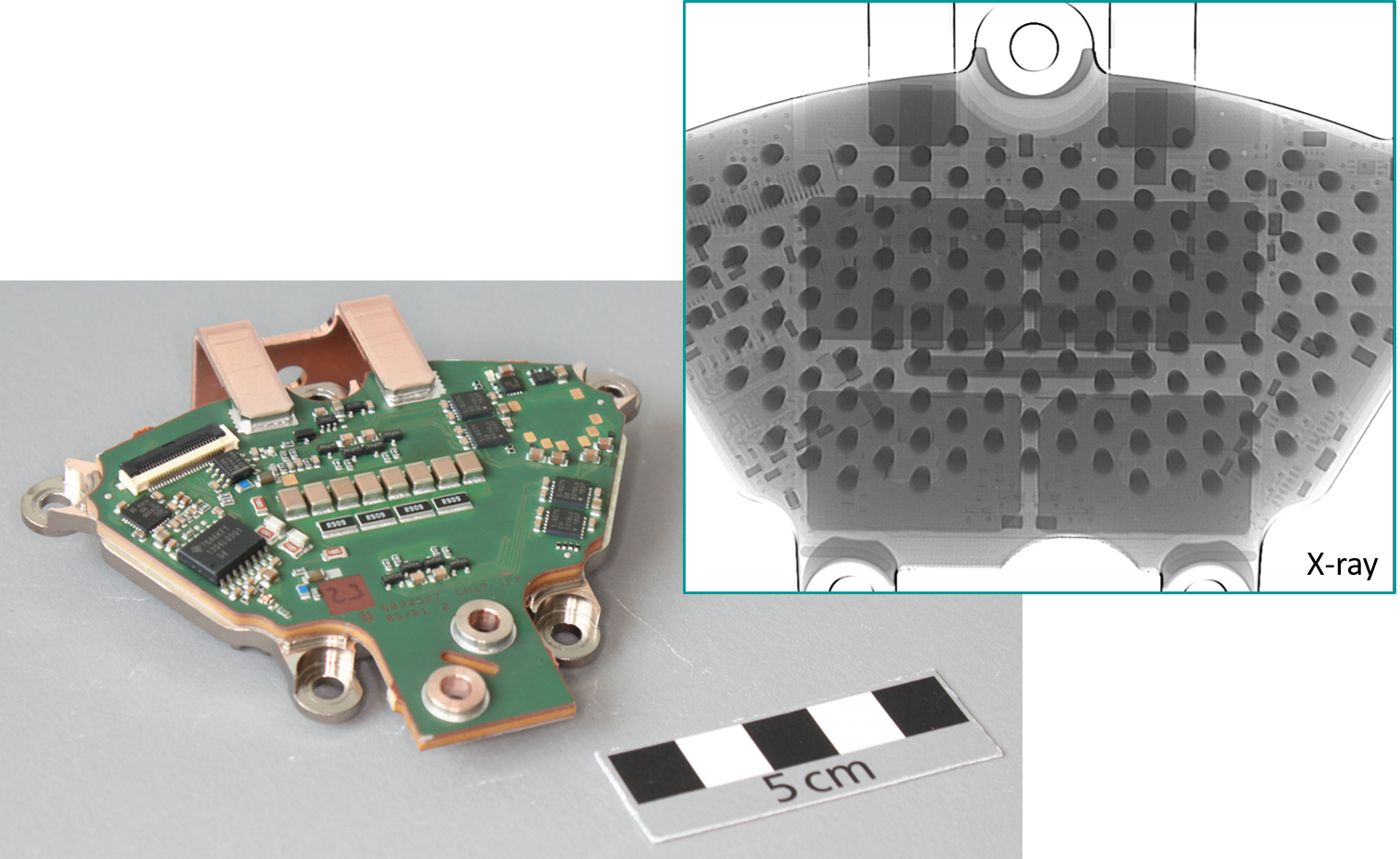

Optimized thermal management is particularly important in power electronics. Improving the thermal connection between the package/module and the cooling structure can increase the service life of the overall system many times over.

Soldered, silver- or copper-sintered connections with correspondingly high thermal conductivities represent a game changer in terms of heat dissipation compared to the typically used polymer thermal interface materials (TIM).

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM