NCA-Bonding interconnection process for E-Textiles

Interconnecting textiles and electronics: A new approach

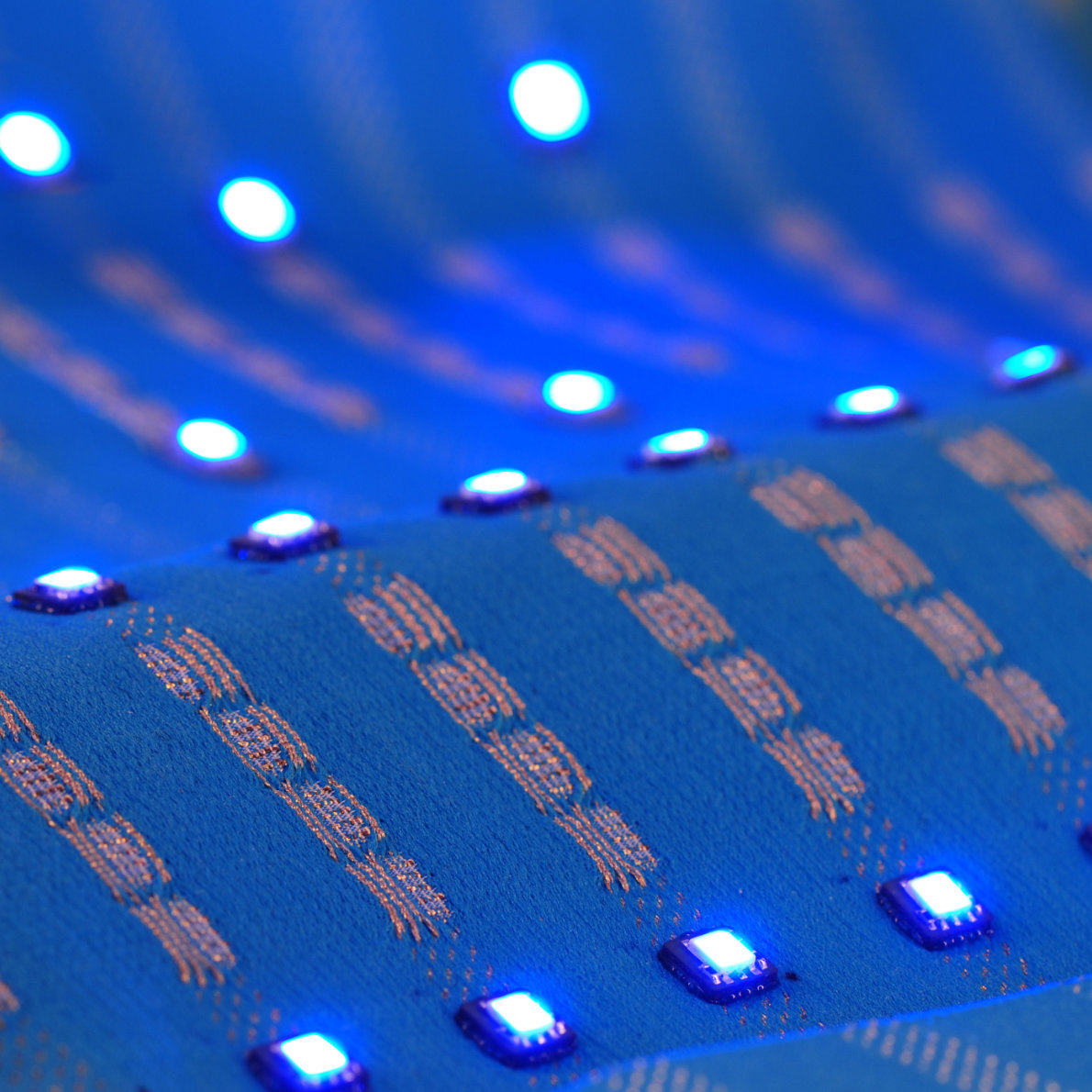

Many E-Textile applications – like systems to monitor vital signs or log ergonomic data, heating pads, lighting, or innovative human-machine-interfaces – require sensors and electronic components integrated into the fabric itself. This combination of electrical components and soft textile materials and the resulting requirements concerning comfort, washability, design, reliability, or signal stability makes the integration process a complex challenge. Interconnecting electronic modules is especially demanding. When it comes to dynamic mechanical stability, reliable contact resistance, or sufficient washability, conventional e-textile contacting methods – snap fasteners, crimping, soldering, embroidering, conductive adhesive, or sewing – often do not lead to satisfying results. The E-Textile bonding technology developed at Fraunhofer IZM solves these issues by contacting electronic modules to textile circuits mechanically and electrically in one single step. The resulting interconnections exhibit outstanding reliability under cyclical temperature and humidity strains as well as excellent washability.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM