More reliability required for electric vehicle electronics

Industry and research institutes plan to develop concepts for increasing bonding stability

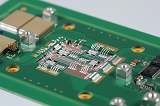

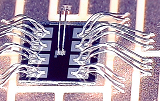

The reliability of power electronic modules required in the drives of electric vehicles is largely determined by the reliability and lifetime of wire bonds that conduct power to the semiconductors (see images). These wire or ribbon bonds are like the main arteries of power electronic drives, because the entire drive power of the electric vehicle passes through them. If one of these bonds detaches, the electric vehicle’s entire drive can fail.

The joint project RoBE - “Robust Bonds in Electric Vehicles” has the ambitious goal of making reliable lifetime prediction possible for each bond at manufacturing and at least doubling bond lifetime.

The German ministry of education and research (BMBF) is funding the project, because finding the solution for such technical conundrums will help decide whether Germany can develop into a leading supplier of electromobility.

A deeper understanding of the influencing factors and the mechatronic relationships in bonding technology is another project goal. By researching, modeling and simulating bonding processes and materials and by developing alternative techniques such as laser welding, the project partners hope to overcome current process limitations.

The project’s most important strategy for pinpointing the required innovations is bringing together the skills and know-how involved at all stages of the design and development chain through cooperation between industry and research institutes. Coordinated by AUDI AG (automotive manufacturer), and with participation by Conti Temic microelectronic GMBH (automotive industry supplier), Infineon Technologies AG (manufacturer of power electronic modules), F&K Delvotec (manufacturer of automated bonders), W.C. Heraeus GmbH (bonding materials manufacturer), LTI Drives (manufacturer of industrial and solar converters), S&F Systemtechnik (automation) and the research institutes Fraunhofer IZM and Fraunhofer ILT, the three-year project will set a new benchmark in bonding reliability.

RoBE is funded by the German ministry of education and research (BMBF) as part of the IKT 2020 program’s topic area “Key Technologies in Electromobility (STROM)” to the tune of 4.96 million euros.

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM