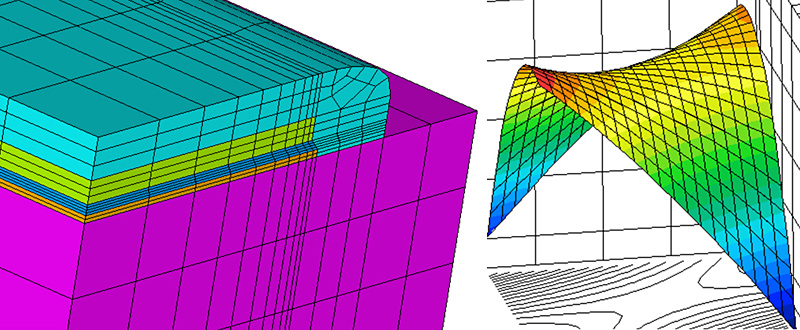

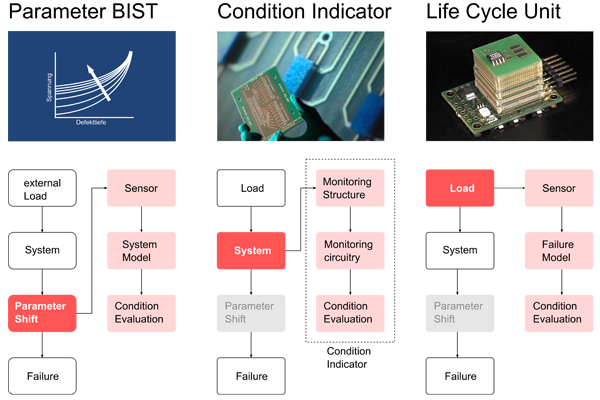

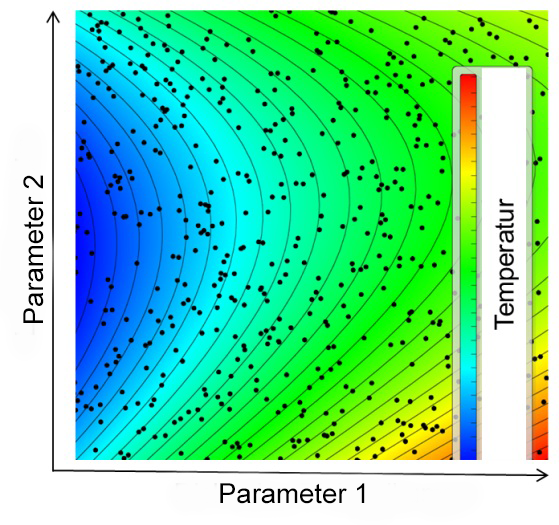

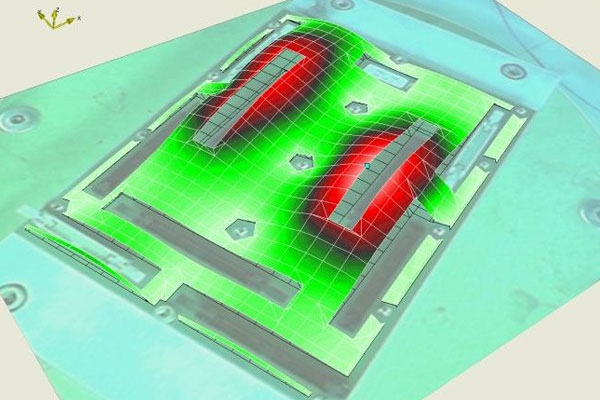

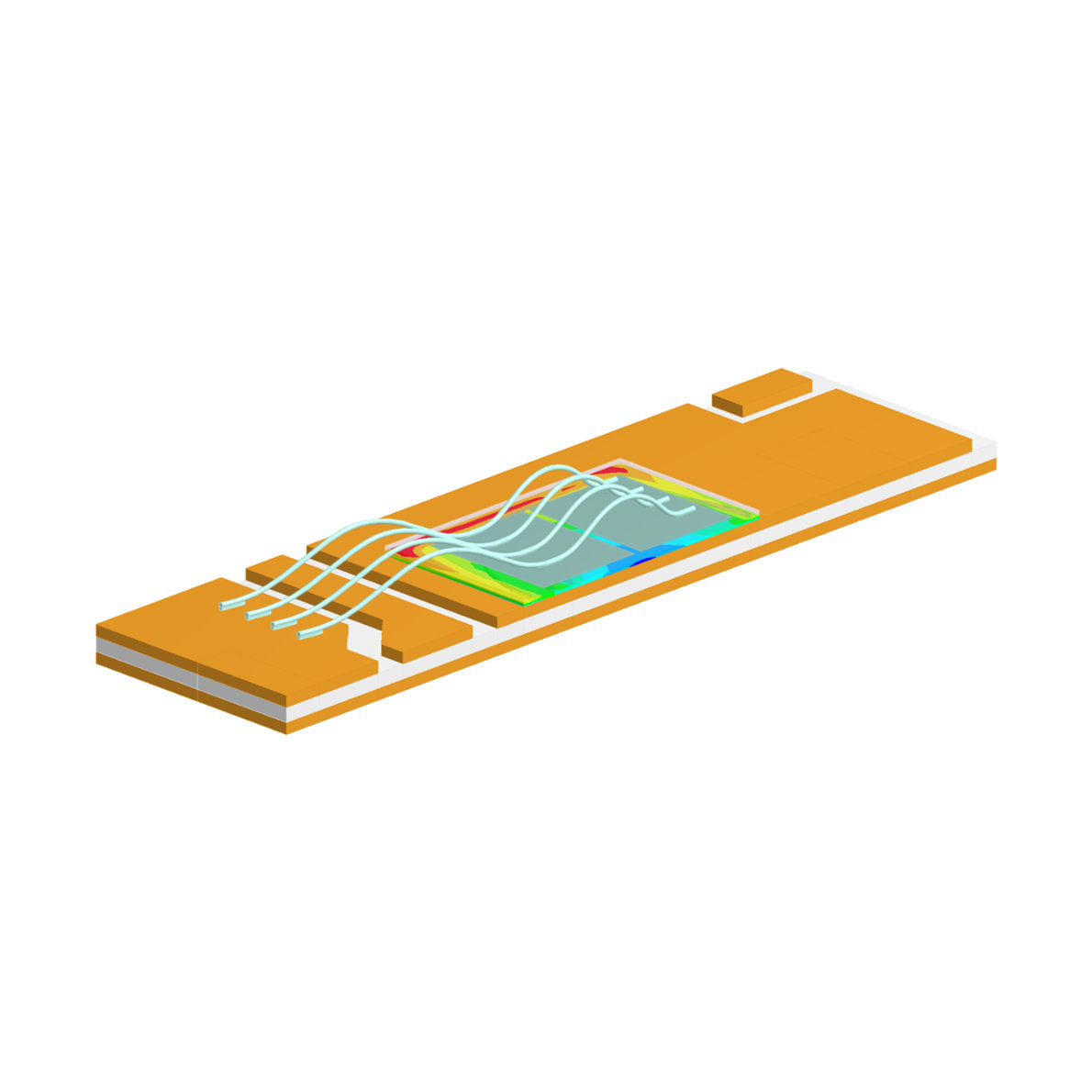

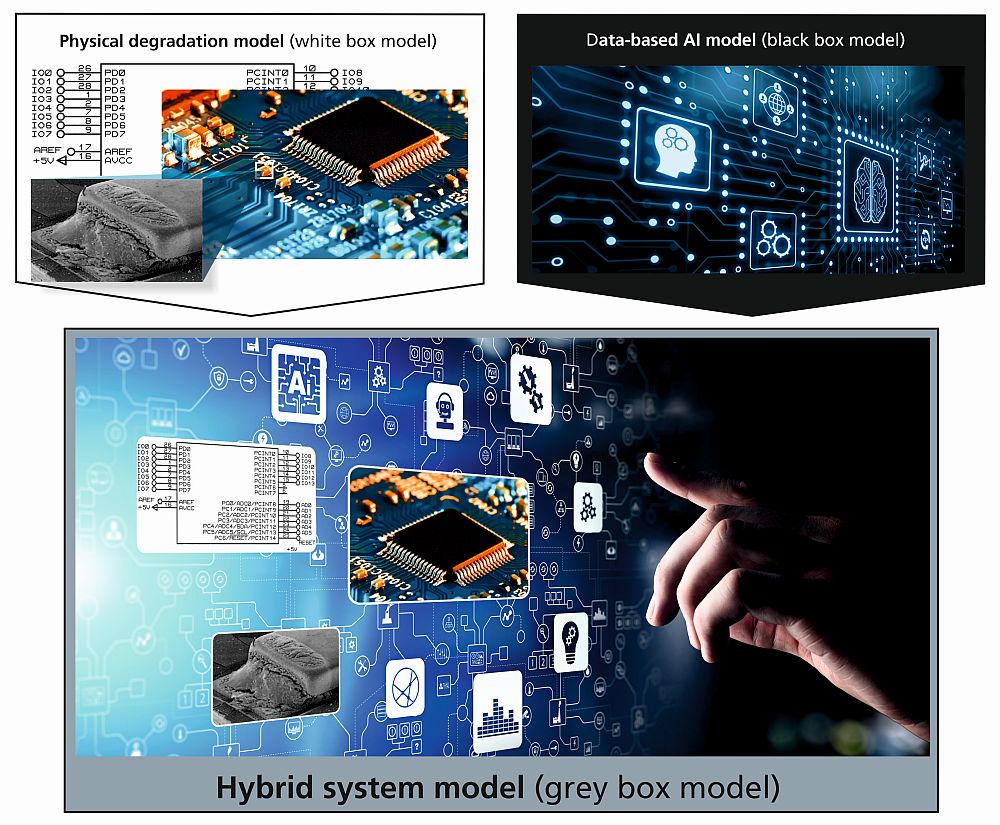

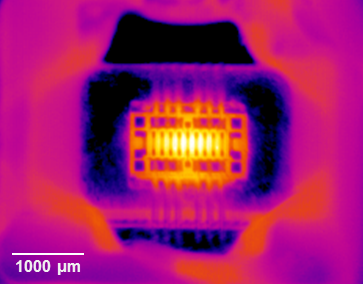

In transdisciplinary teams, we develop innovative, customer-oriented solutions for robust, energy-efficient and sustainable electronic systems. We ensure their reliability through application-specific system design, qualification, weak point analysis and optimization both at the system and technology level. Experimental and simulative methods are also developed and applied for this purpose. Reliability assessment and tamper detection of complex electronic systems is increasingly carried out using hybrid (grey-box) modeling approaches. Functional circuit structures are extended by physics-based model approaches and data-based, AI-supported evaluation methods (digital twin).

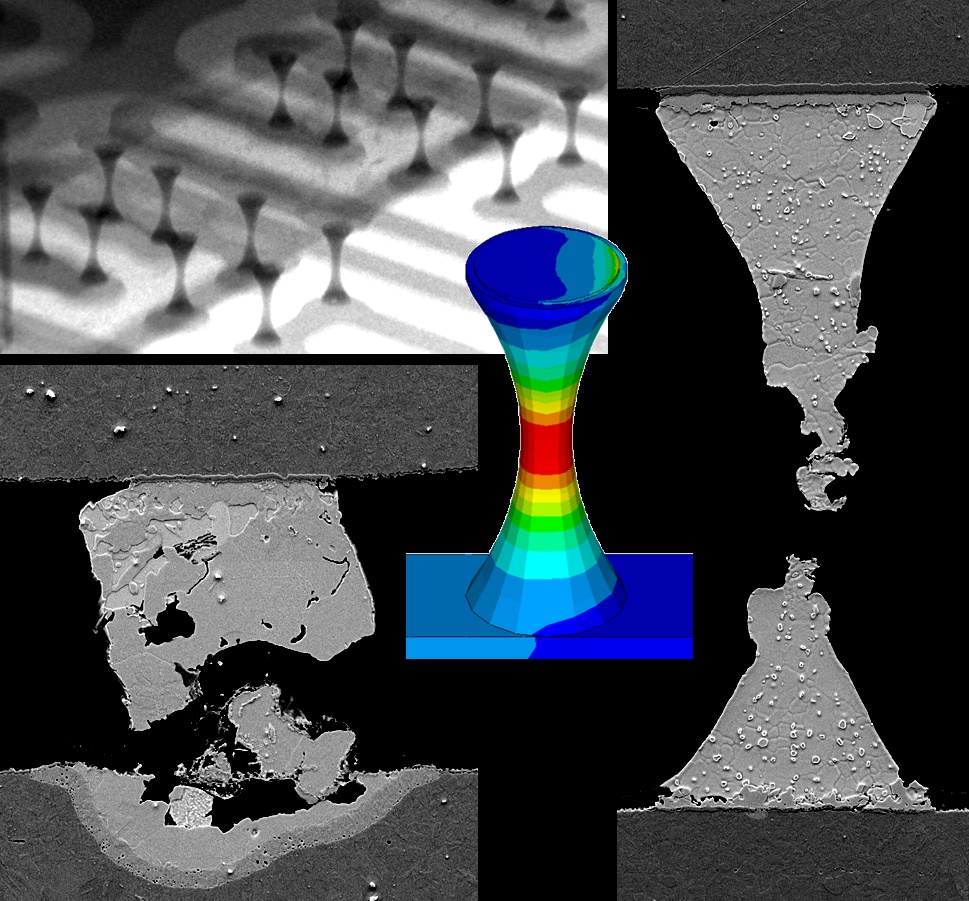

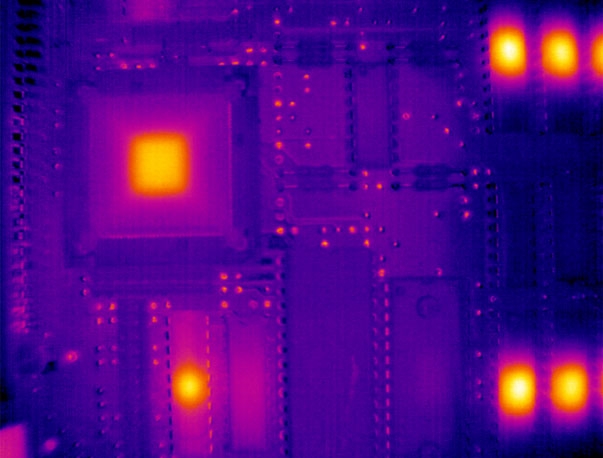

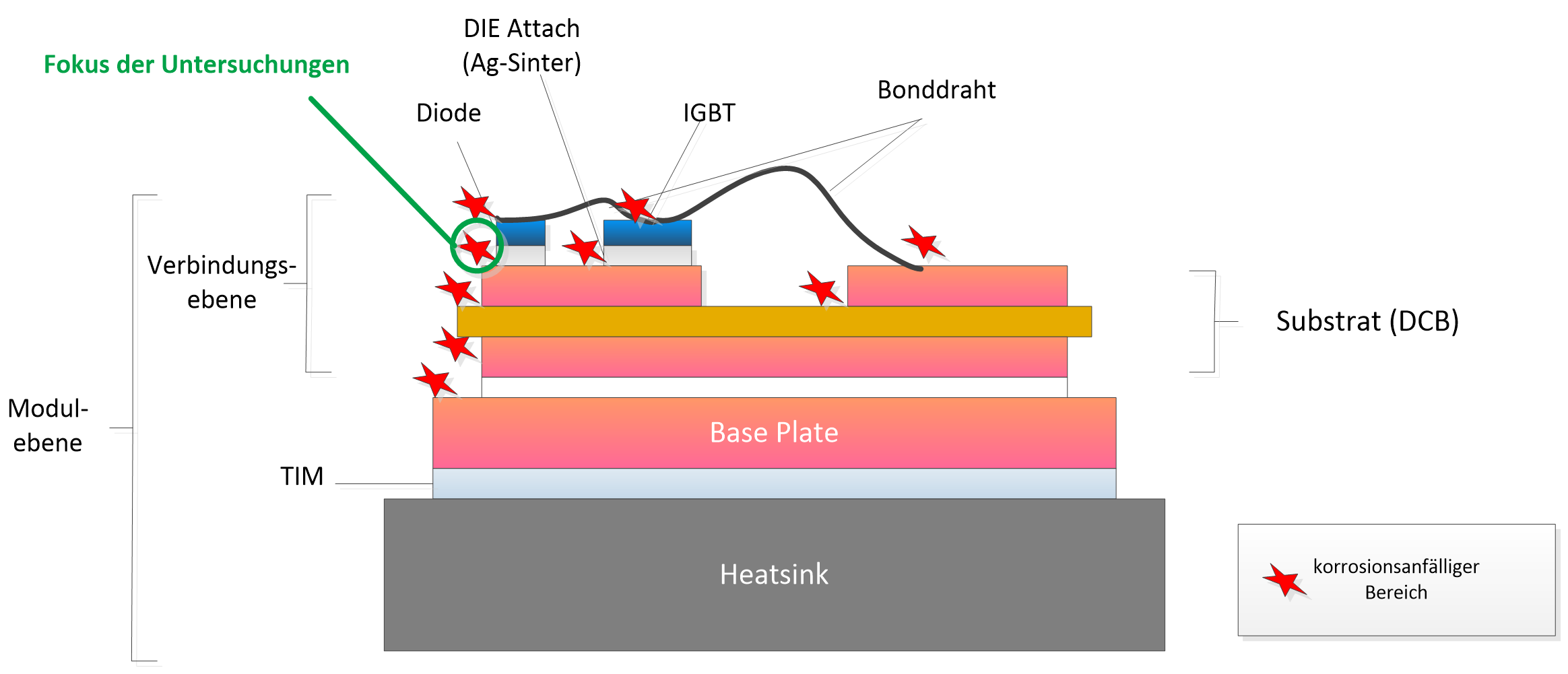

Taking advantage of our extensive technological expertise combined with the analytical resources of Fraunhofer IZM, we also carry out failure and root cause analysis of electronic assemblies or power electronic modules. To evaluate the reliability and robustness of electronic assemblies and systems, we cover a wide range of defined stress tests and develop target-oriented stress scenarios on the basis of application-specific mission profiles.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM