Photonic Packaging & Interconnection Technologies

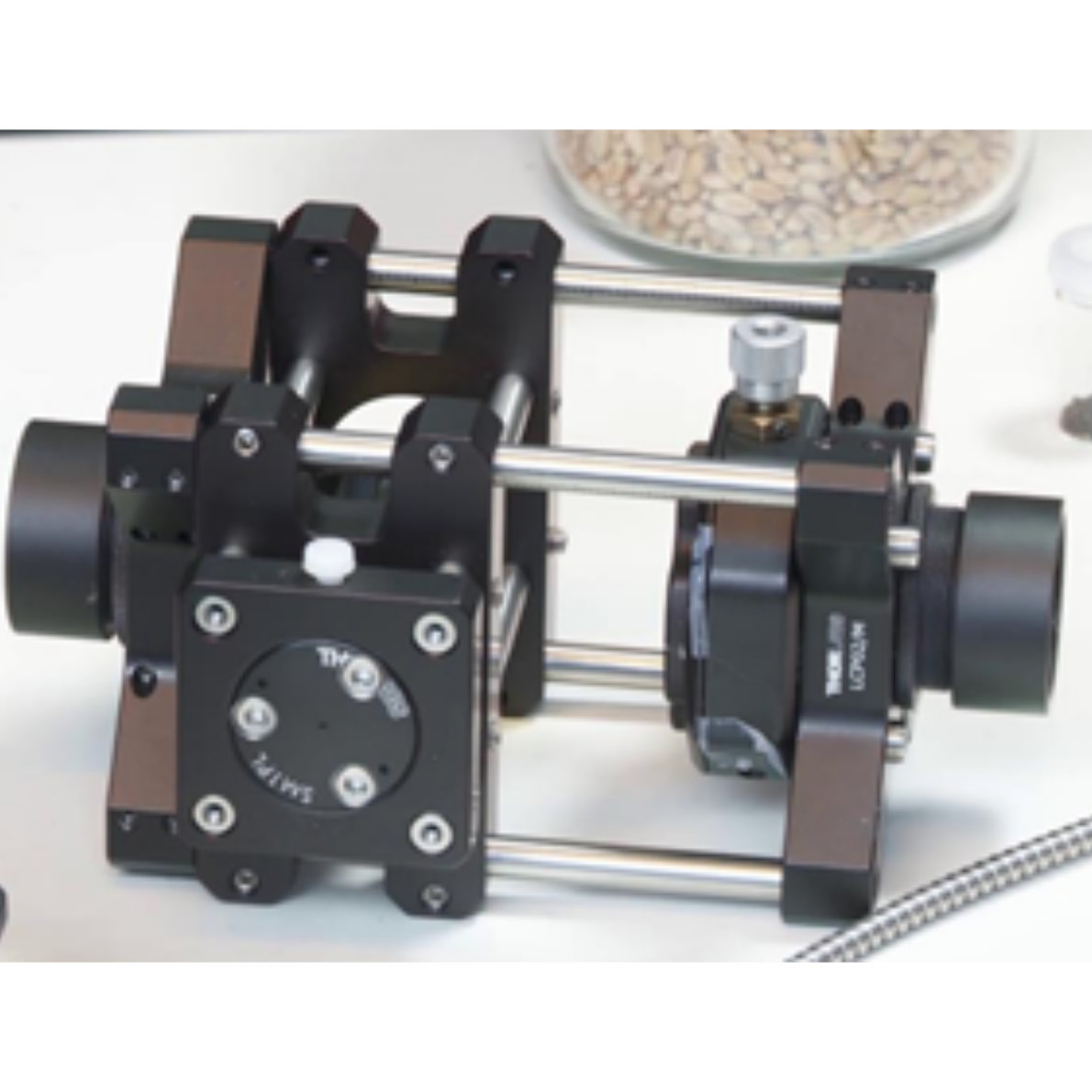

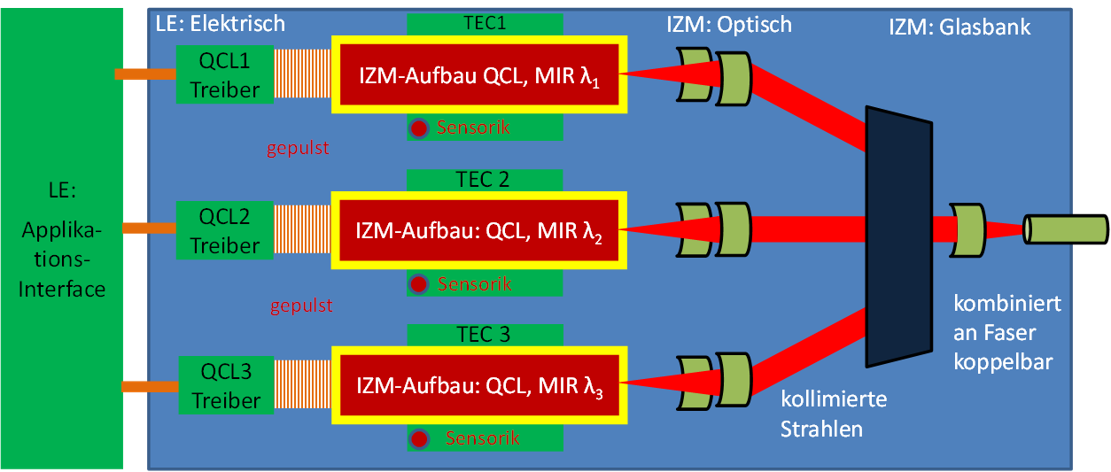

Unsere Kernkompetenz ist die Entwicklung innovativer Packages für Komponenten und Systeme aus Mikroelektronik, Optik und Mikrosystemtechnik. Wir sind Entwicklungspartner für unsere Kunden aus Kommunikationstechnik, Sensorik, Consumerindustrie, Medizintechnik und Lasertechnik für hybrid-integrierte Prototypen und Kleinserien auf Basis verschiedener Materialien (Polymer, Glas, Keramik, Glasfaser, Silizium). Der Einsatz von Technologien der Mikrosystemtechnik ermöglicht höchste Präzision und die Automatisierung der Prozesse.

Durch kundenfreundlich organisierte Projekte profitieren unsere Kunden von der systematischen Simulation, dem kundenspezifischen Entwurf und den Möglichkeiten der hochmodernen Anlagentechnik sowie Untersuchungen der Zuverlässigkeit und der Fehleranalyse. Diese breite Basis dient zur Entwicklung kundenspezifischer Lösungen und wissenschaftlichen Weiterentwicklung photonischer Aufbau- und Verbindungstechnik. Unsere Kunden können die Inertialkosten und das Risiko ihrer Produktentwicklung reduzieren und schneller am Markt sein.

Fraunhofer-Institut für Zuverlässigkeit und Mikrointegration IZM

Fraunhofer-Institut für Zuverlässigkeit und Mikrointegration IZM