The core objective of the project is the development of a hybrid self-validation approach for safety-critical electronic applications. Based on the real, locally available data in the field, a unique system characterization is performed. Thereby, critical system conditions can be prevented as well as redundancies and over-dimensioning of the system can be reduced.

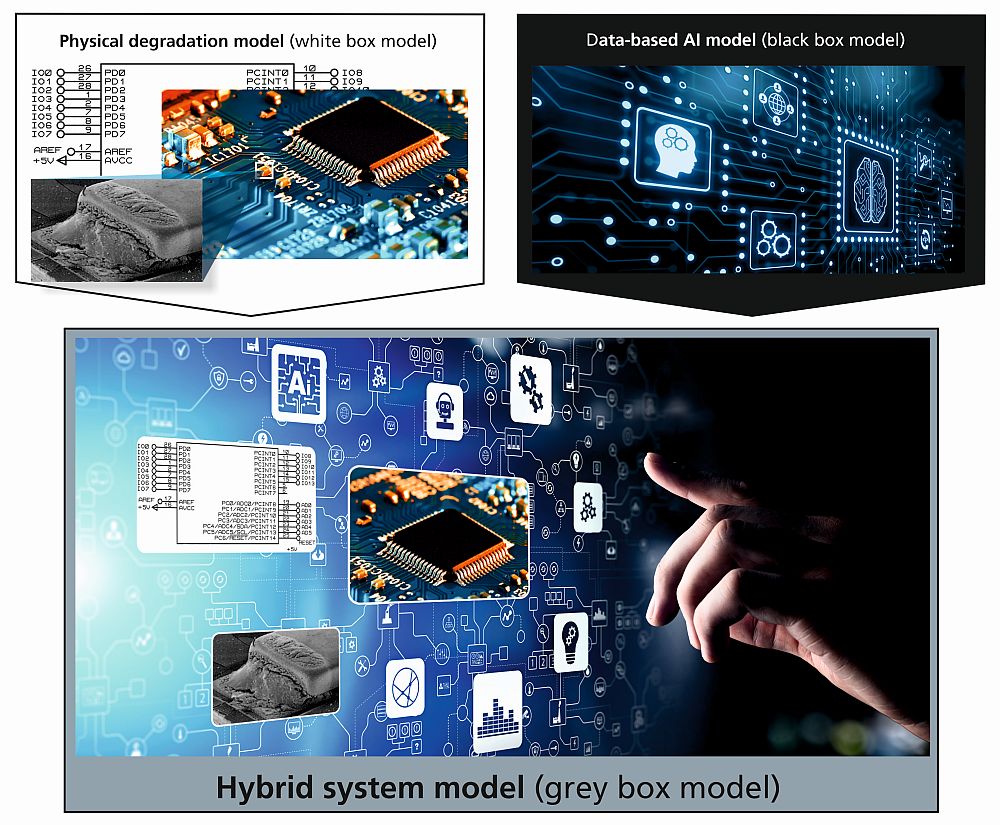

Within the project, physical degradation models (white-box models) and data-based AI models (black-box models) are specifically combined and merged into a hybrid model (grey-box model) for explicit system characterization during its life cycle as well as for ensuring functional integrity. Hybrid modeling is used to create suitable distinctive signatures of the assemblies in a system, also known as digital twins. In addition to the initial state of the assemblies, e.g., process variations (void percentage in the solder, solder geometry, positioning accuracy, etc.), the effect of field stress on functional integrity is also taken into account.

For the establishment of a database and the experimental evaluation of the models, multiple prototypes for the specific applications with a wide variety of design elements are developed. This will allow the limits of the model to be tested and the functional scope of the models to be increased step by step. Furthermore, a novel test and measurement methodology for the online acquisition of characteristic changes, load conditions and system manipulation will be developed for this purpose.

In order to achieve an efficient data flow, a software and communication architecture is being developed through which the data can be pre-processed and coupled with the models. As a solution strategy, a distributed, service-oriented software architecture is being pursued and researched, which provides scalable and component-specific prognosis and decision-making functions.

As a result, the hybrid grey-box model approach enables early lifetime prediction of the electronic system during operation, detection of system manipulations, and determination of the influence of manufacturing-related tolerances on the system condition.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM