Micro battery

1. Customized secondary micro battery

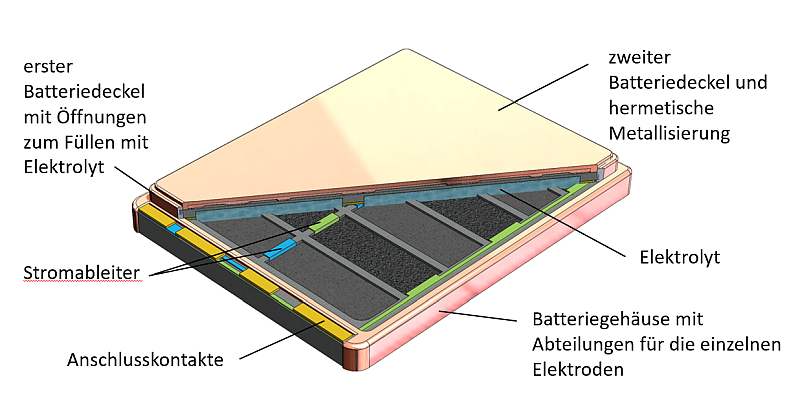

The silicon-integrated lithium micro battery developed at Fraunhofer IZM can be used wherever extreme miniaturisation of electronic systems is required.

Typical applications are e.g. active RFID, radio sensors or medical implants (e.g. micro hearing aids, eye pressure and blood pressure sensors).

Parameters such as shape, size, voltage, capacitance and power can be customised to suit the application.

In addition, for self-sufficient sensors that harvest their energy from the environment, it is important that the memory is only as large as absolutely necessary, since the self-discharge current scales with size and must be compensated by the harvester.

The main parameters are summarised in the table below:

| Size [mm] | 2x2 ... 2x12 ... 12x12 |

|---|---|

| Thickness [mm] | 0.5 |

| Capacity [mAh/cm²] | 0.5 ... 1.2 |

| Energy [mWh/cm²] | 2.5 ... 5 |

| Mean discharge voltage [V] | 2.5; 3.7 |

| Max. discharge current [mA/cm²] | 2 - 6 |

2. Materials development and testing for lithium-ion batteries

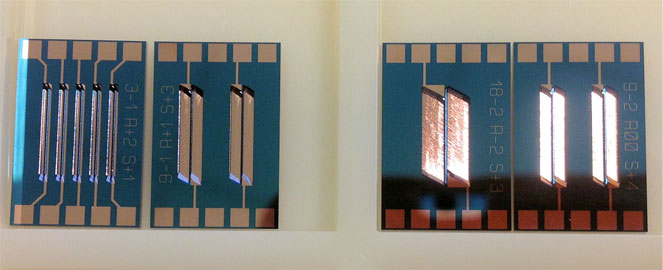

Fraunhofer IZM's micro-battery technology is being further developed and expanded into a test platform for materials research in electrochemical systems. By integrating reference electrodes and arranging many test structures over a large area, several hundred test cells can be encapsulated and tested on a substrate at the same time. Programmable volume dispensers are used to apply combinatorial material variations.

This makes it possible for the first time to use high-throughput methods at the cell level. Due to the large number of samples, degradation mechanisms and cycle life can be studied in more detail and statistically verified, e.g. by simultaneous tests at different temperatures and current densities. Since the various factors and degradation mechanisms are interrelated, a multi-factorial design of experiments is required, which can be carried out very cost-effectively using the test cell arrays.

Clean room manufacturing and single use of each cell ensures freedom from contamination. Battery laminates are tested in standard fixtures such as Swagelok and EL-Cell.

Other components of the test concept include

- Standardised test layouts,

- A simple setup for electrode assembly and case closure,

- A contacting device and a multi-channel or multiplexed test system for electrical characterisation.

- A database system for convenient management and evaluation of array test procedures and test data.

3. Battery and accumulator test service

The battery laboratory operates as an independent test centre for batteries and accumulators. There are several automated test systems (MACCOR, BASYTEC) with more than 400 calibrated channels, as well as controllable climatic cabinets and PC-controlled individual measuring stations, with which a large number of customer-specific tests can be carried out. Testing to standards is possible, e.g: IEC 509, IEC 21A 227, 228,230. 239,256, IEC35 1025, IEC 86-4, DIN, EN 60285, 60622, 60623, 61434, 60086, DIN IEC 61960.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM