Molten salts exhibit a phase variation from solid to liquid over a wide range of temperatures, making them of great importance for industrial uses such as batteries, pyrochemical reprocessing of nuclear fuel, synthesis and catalysis. In optics they are also exploited to typically manufacture integrated glass waveguides where the chemical-physical properties of glasses are changed.

Fraunhofer IZM had the initiative to exploit molten salts by developing an innovative hydrofluoric acid-free etching process. This allows to manufacture reliable glass fiber optic components and planar glass microstructures with optical or fluidic functionality. Furthermore, this process provides an ultra-flat and strengthened surface after treatment with molten salts. It means that surface defects, e.g., roughness and microcracks, are not present as in hydrofluoric acid based etching processes. A great benefit here is gained when the glass is further processed with heating techniques, since this prevents irreversible damage to the glass.

A molten salt etching station has been designed and built to etch glass with defined etch and process parameters. The etching attack of the molten salt is similar to the wet etching that uses a mixture of etchants to remove the glass material. Such an etching station was the basis for the development of a first-generation modular demonstration plant which is able to simultaneously etch up to 12 glass fibers and 4 glass substrates in a single run. High process control, low chemical disposal costs and scalability to panel format are some of the benefits displayed by this molten salt process and its implementation in a plant.

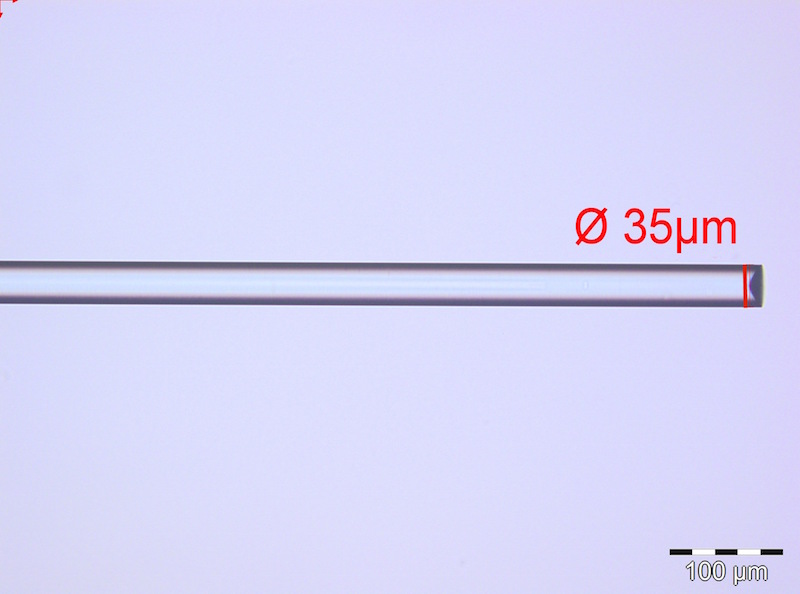

Several tests have been successfully conducted using fused silica optical fibers and borosilicate glass substrates, showing stable and uniform reduced zones. In particular, etched glass fibers are used for the development of optical components such as tapers, tips, bundles and couplers. Molten salt treatment of laser-structured glass substrates has been also performed where the glass surface was significantly improved.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM