Specialist article by Dr.-Ing. Mathias Böttcher

IoT Systems for SMEs

The cooperative initiative "Universal Sensor Platform" (USeP) is vivid proof of how effective project work can pay off in research and development and within the "Research Fab Microelectronics Germany". Scientists from several Fraunhofer Institutes contribute their specialist expertise to create a platform for innovative, highly integrated, and individually customizable IoT systems tailored to meet the practical requirements of small and medium-sized enterprises. The contribution of Fraunhofer IZM lies in the development of a sustainable and economical packaging technology for these systems. In partnership with the fellow Fraunhofer Institutes IIS, EAS, and IPMS and the industry partner GLOBALFOUNDRIES and supported with funding from the European Regional Development Fund and the Free State of Saxony, the project is using its resources to produce immediate results of real value for industrial applications. Sensry, the spin-off launched by the project partners, is set to ready and provide the resulting platform for SMEs.

The Internet of Things is opening new avenues for innovative applications and business models and increasingly making its way into all aspects of modern commercial and private life and society at large. To stay competitive, small and medium-sized enterprises (SMEs) need to keep up and include more and more IoT capabilities into their products, services, and applications to enable physical and virtual products and devices to communicate and work together through the power of novel information and communication technology. Advanced sensors and actuators are also being retrofitted to established systems to capture different object types, states, and functionalities.

One challenge remains: System developers typically rely on using industry-standard components and are limited in their ability to adjust their solutions to the specific IoT requirements they are aiming for. Designing custom, application-specific components with the advanced technology to achieve this feat is often out of the reach for smaller-scale businesses. Developing new technologies or modifying packaging processes for a custom integration of sensors or other electronic components is a costly and time-intensive proposition. This is where the idea of USeP came into the picture in August 2017. A modular and universal sensor platform would offer a ready-made component for highly integrated IoT systems, with a highly flexible central IC produced with 22nm FDX technology. This heart of the design possesses digital and analogue interfaces to match almost all common sensor and actuator types and include integrated data conversion, storage, processing, and encryption capabilities as well as versatile communication interfaces for wired or wireless data transfer and local power management for custom sensors. Put together, this represents the backbone for a fully flexible and highly capable platform.

Another essential element for a customizable setup with sensors and communication interfaces lies in the dedicated design of a flexible, highly dense packaging solution. The concept allows individual application scenarios and enables both the cost-saving production of the core IoT elements with the energy-efficient 22FDX technology of GLOBALFOUNDRIES and the flexible adaptation of these core elements to the specific requirements of the finished system implementation.

The user can start with the platform to quickly put together a custom configuration and move on to prototype or full-scale production. The interdisciplinary project empowers young start-ups and established SMEs to stake their claim in their market with highly specialist products, benefitting from low-cost, but high-speed product development cycles.

Custom solutions and accelerated development

One unique aspect of the project is how the researchers and scientists are cooperating with their industry partner GLOBALFOUNDRIES in the pursuit of their mission. The Fraunhofer Society is contributing across multiple sites and institutes, with specialists for IC design, software, data security, reliability, sensorics, and packaging doing their part in developing the system. The Fraunhofer Institute for Reliability and Microintegration IZM alone adds researchers from three departments and two sites to the development and implementation of the assembly and packaging technology for the sensor platform. The colleagues from Berlin and Dresden are bringing in the complete range of expertise and services needed for the USeP: from the creation of high-density multilayer wiring with specialised interlayer vias and contacts to accommodate high-pole Si chips and integrated passive components to wafer modling or the production of wiring and contact structures on the package surface, the SMD assembly of sensors and actuators, wafer-level balling, or the physical characterization of the assemblies.

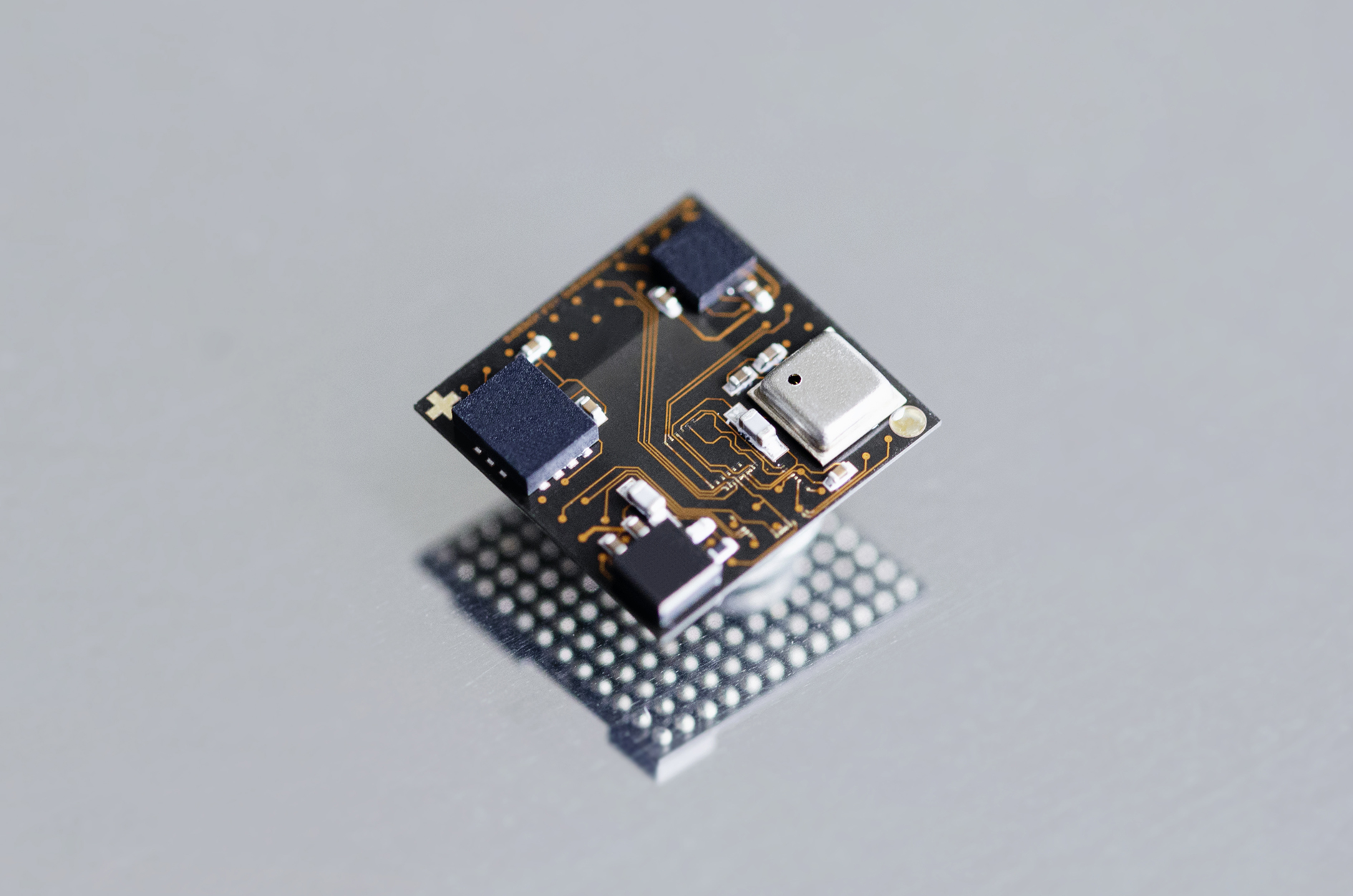

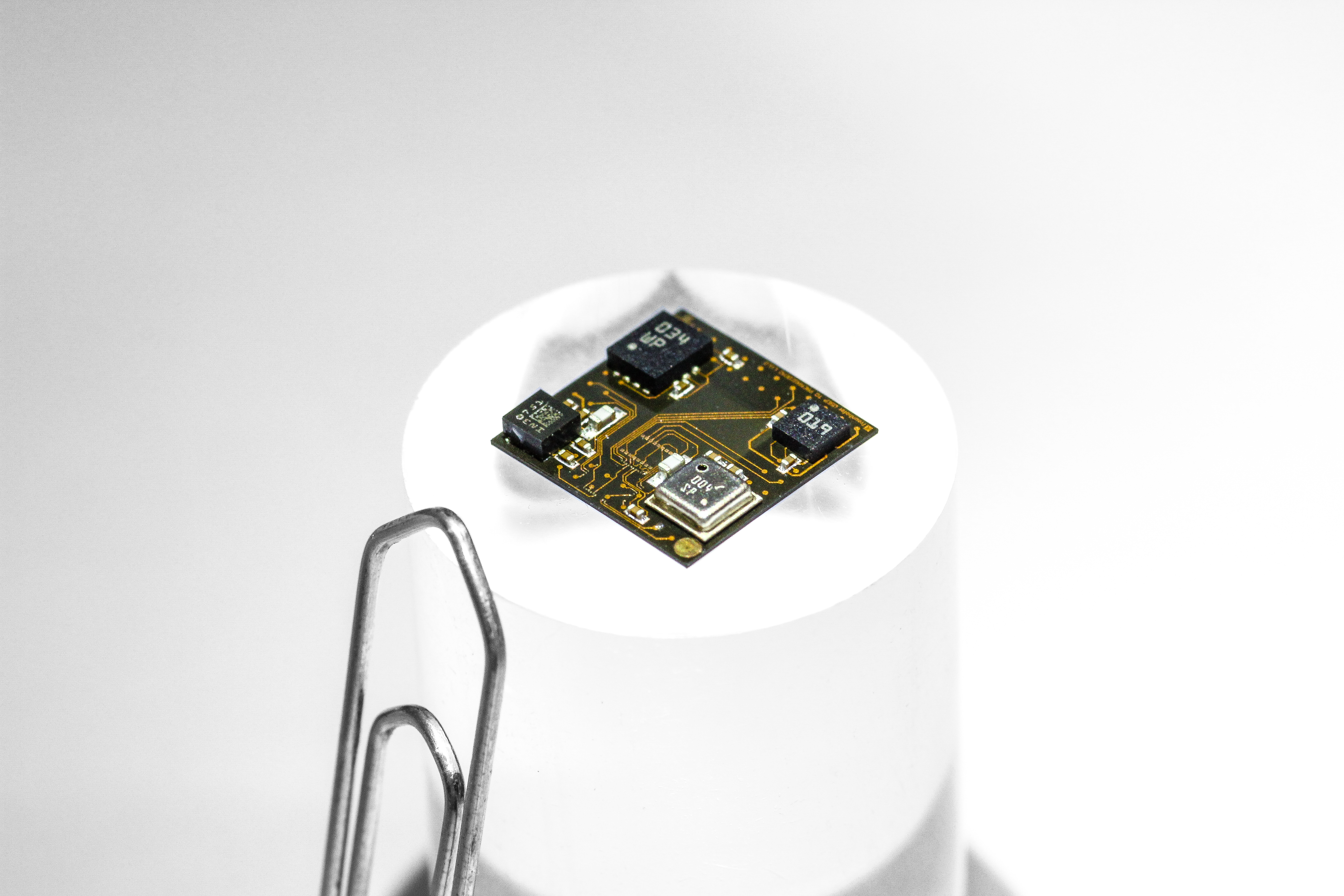

Combined with the expertise of other Fraunhofer Institutes, a new package is being developed to house the SoC developed in the project and made by GLOBALFOUNDRIES with its 22nm FDX technology as the heart of the solution. For this purpose, a fan-out wafer-level package with RDL first / chip last is being adapted for the sensor system, to be adapted and expanded by adding components for custom applications on the top surface.

The implementation of the system concept requires an innovative packaging approach, cutting-edge manufacturing processes, and a finely-tuned process flow as well as advanced materials and specially adapted design rules. A first set of demonstrators has been produced as proof of concept, including the technologies required for the hardware solution, and potential for optimization has been identified to feed a roadmap to take this specific packaging technology to the next level. Going forward, the work on the project will focus on further increasing the density of the design, implementing chiplets, and integrating additional passive components for high-frequency applications.

All major components of the platform are now in their advanced development and testing stages, and the second quarter of 2020 will see the integration of the SoC in the package platform. From that point on, nothing will stand in the way of the construction of working demonstrators.

Sensry GmbH will sample and ready this advanced IoT system for industrial use and market launch. The finished platform concept will be ready to have its design adjusted to match each customer’s specific requirements on different levels.

More details about the USeP project, in particular its innovative packaging technologies, SENSRY, and the project representatives can be found at: https://www.izm.fraunhofer.de/de/abteilungen/high_density_interconnectwaferlevelpackaging/projects/USeP.html#tabpanel-1 and http://sensry.net/.

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM