Fraunhofer researchers rely on the right material for the mobile communication standard of tomorrow

Simulate until it sparks

The performance of radio-frequency applications such as 5G or radar depends mainly on the materials and interconnects used. In order to investigate and optimize these, a new research group has been founded at Fraunhofer IZM in Berlin. Drawing on the expertise of the researchers, high-frequency structures are assembled in such a way that facilitates optimal wave transmission.

According to a study by technology analysts Yole Développement, the market for radio-frequency modules in the telecommunications sector alone will more than double in the next five years*. These as well as developments in the automotive and radar sectors illustrate the fact that radio frequency not only already forms an integral part of today's world but is also paving the way for future innovative electronic solutions.

The Fraunhofer Institute for Reliability and Microintegration IZM has been developing technologies for radio-frequency applications for over 20 years. Now a new group led by Oliver Schwanitz has been established to investigate the requirements for all these developments: Radio-frequency materials and their interconnection technologies. This covers an enormous spectrum, since the decision for a substrate material is also decisive in determining how much power is transported, and therefore also which applications it can be used with.

The group has been involved in important research projects from its inception. For example, it is currently developing millimetre-wave modules in conjunction with other working groups for future radar applications in vehicles and is doing research into the next mobile communications standard as part of the 6GKom project. Companies from other fields, such as the chemical or pharmaceutical industry, also request the services of Schwanitz’s group to help characterise the electrical values of their materials. As part of its specialization, the ‘RF Materials & Interconnects’ group can investigate which materials are suitable for use in RF applications without sacrificing or changing performance.

Before taking measurements, for example, simulations are created that depict the ideal course of the signal In the course of the project, the researchers test materials and interconnections so that the applications can be realized as close to the simulation and with as little loss as possible. The basic goal is to gain a holistic understanding of the influences of the radio-frequency properties of materials. The central point here is that the permittivity and the dielectric loss factor of a material significantly influence the expected performance of RF structures. In order to operate in a higher frequency range, such as that required for 5G and radar, these values must be determined in advance – only then can the system be expected to work at the planned frequency and perform accordingly.

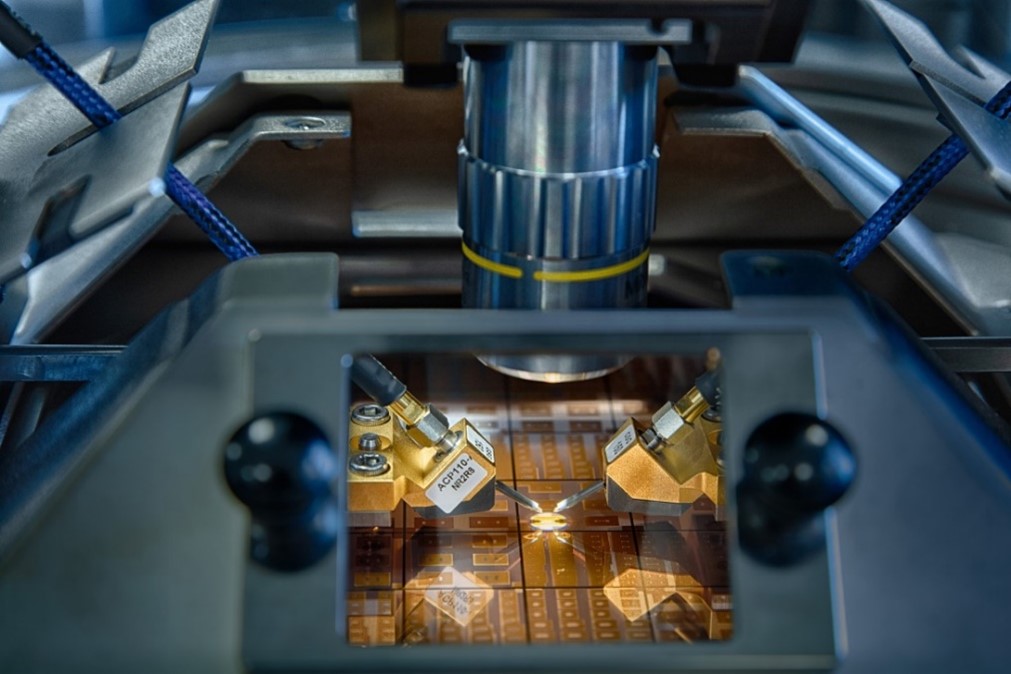

It is impossible to measure radio-frequency technology with conventional multimeters because the amplitudes are so small and location-dependent, e.g. in the millimetre wave-range, that other measurement techniques are required for validation or verification. The group's researchers have a semi-automatic helper for their investigation of radio-frequency materials and their interconnects: A network analyser with wafer prober, which is part of the Research Fab Microelectronics Germany at Fraunhofer IZM. This device enables researchers to investigate RF structures across a wide range of temperatures (-20°C to 150°C) up to a frequency of 500 GHz.

Because of its applicability in all RF developments, the Group's expertise is already in demand in many projects – but they also have plans of their own for the future. Group leader Schwanitz explains: “I hope we can move towards material development as well. We are particularly interested in so-called metamaterials, i.e. those whose electrical properties do not occur naturally. These can be used to create very special properties, such as significantly lower loss properties, with rising temperatures. But these are still a long way off, and in order to achieve them or make them industry-ready, a transformation from a theoretical research vehicle to a concrete and functioning prototype must take place".

But for now, the group is mainly focused on existing projects and making significant contributions to the realization of innovative radio-frequency applications through material characterization and interconnect design. One of the most important schemes is the 6GKom project within the framework of the ForMikro funding guideline from the Federal Ministry of Education and Research. In this project, a module is being developed with other project partners, which is intended for use in the coming 6th generation of mobile communications. "This may sound strange", says Schwanitz, "since the 5G mobile radio expansion in Germany has only just begun, but it is essential for Germany as a research location to keep up with the international competition in this regard.”

*Yole Développement (2020). GaN RF Market: Applications, Players, Technology and Substrates 2020. Market Technology Report 2020. S. 30.

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM