System Reliability

The safeguarding of the reliability begins in early design phases of the development process of a system. Existing systems can be optimized based on statistical methods.

We provide expertise in the following area:

- Determination of the total failure rate of electronic systems by means of failure rate catalogues

- Determination of system reliability (MTBF:mean time between failure of a system capable of repair, MTTF:mean time to failure)

- Selecting components on the basis of MTBF-/MTTF calculations

- Strategic planning (Maintenance Cycle Management

Application of the Machinery Directive

Compliance investigations in accordance to the Machinery Directive 2006/42/EC involve evaluations of the failure probability and the safety of electrical, electronic and mechatronic control systems.

We provide expertise in the following area:

- Determination of diagnosis coverage

- Classification of safety-related parts of control systems (SRP/CS) in performance level

- Determination of system reliability (MTTFd: mean time to dangerous failure)

- Analysis and testing of safety functions Failure analysis

Analysis and metrological monitoring of systems, and component structures and materials used, are performed according to the state of the art. Recommendations concerning processes and design will be made.

We provide expertise in the following area:

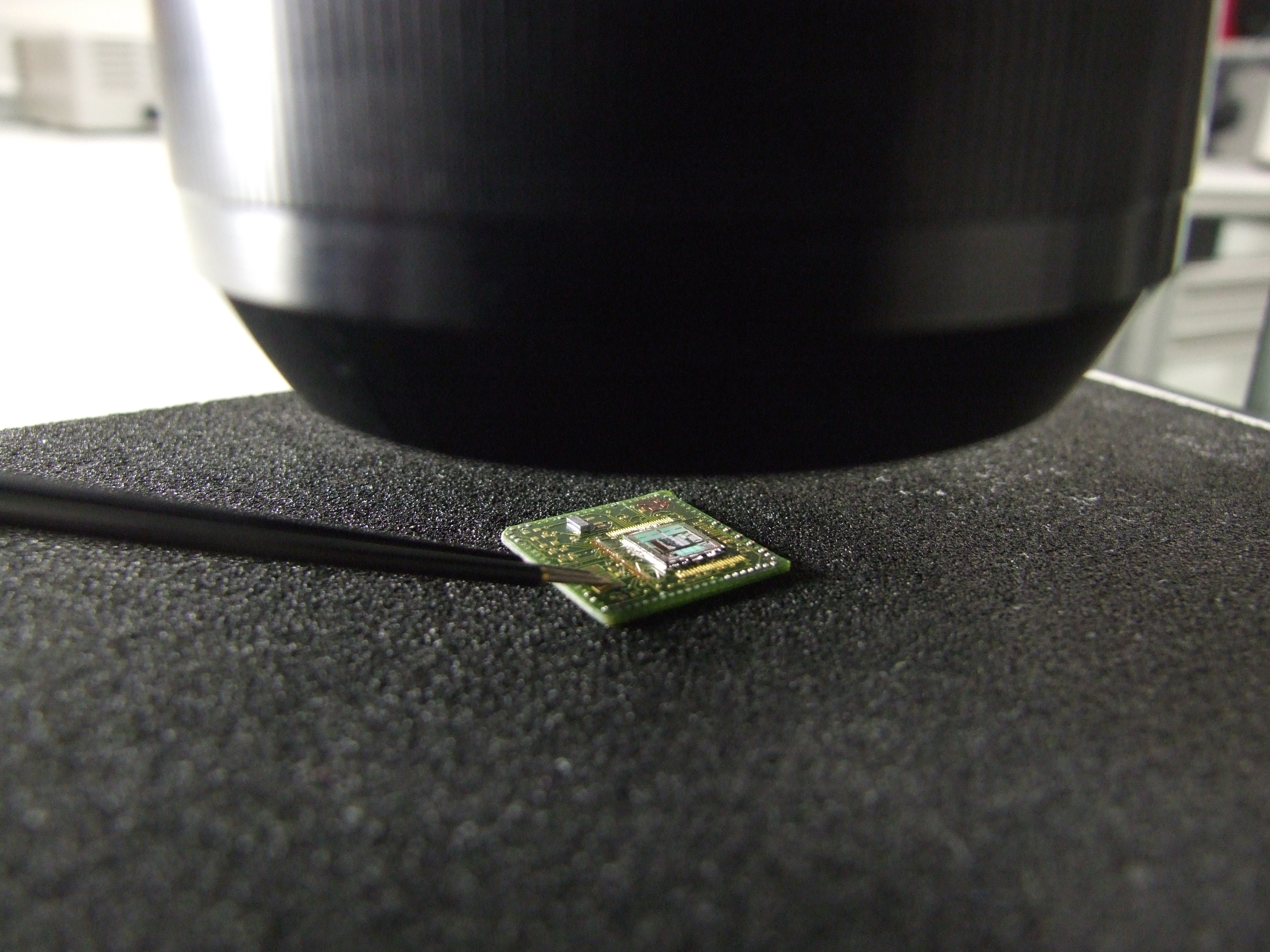

- Optical inspection (component analysis)

- Thermo graphic analysis (Lock-in)

- Electrical examination

- Material characterisations, e.g. coating thickness measurement (RFA, Couloscope)

- Metallographic analysis (FIB, EBSD, REM, EDX)

- Non-destructive analytical methods (REM, X-Ray)

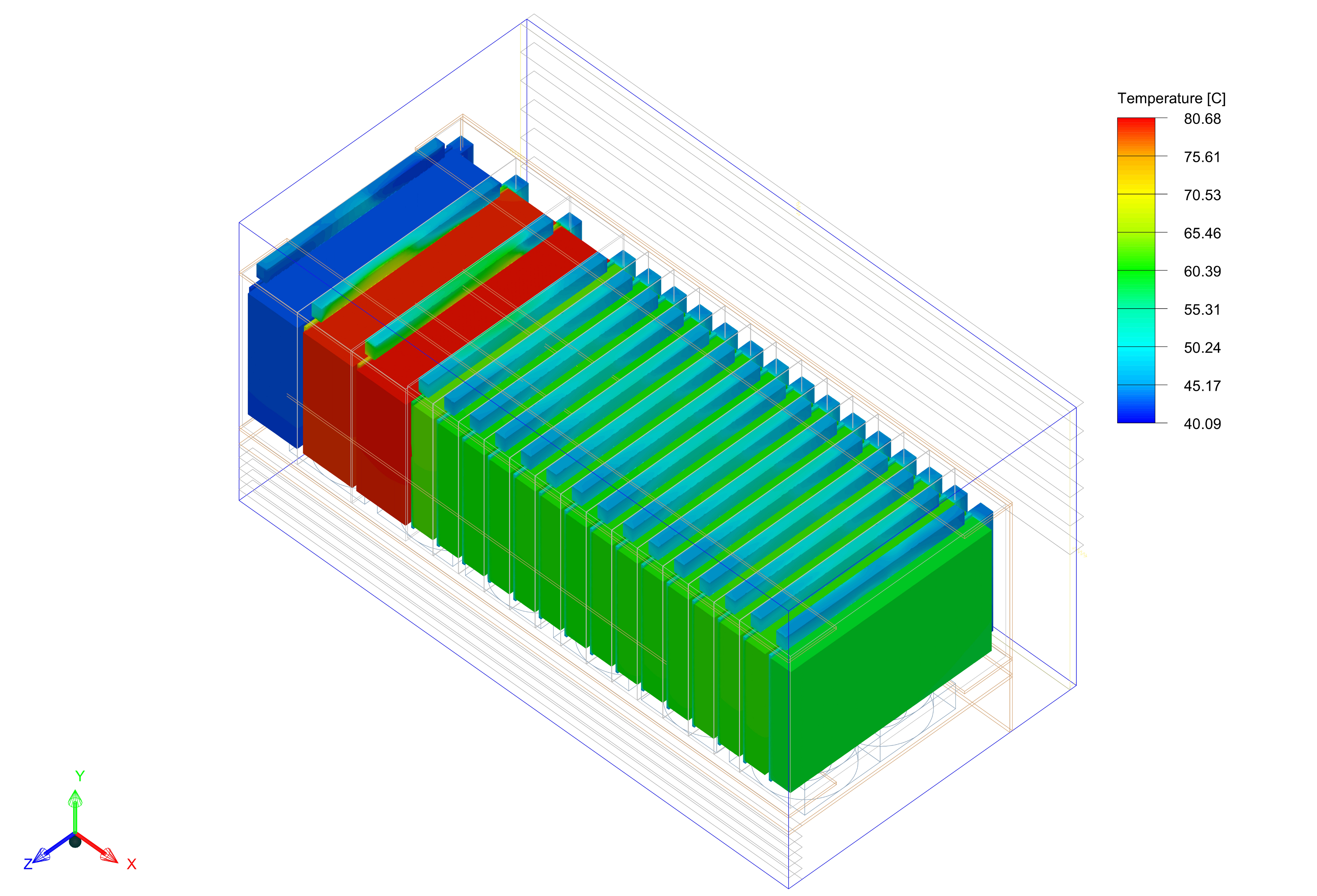

- System simulation (FEM, FVM)

- Combined and accelerated stress and ageing tests (vibration, temperature cycle, electromigration, moisture)

- Assessment of the condition of a system bydetection of stress, data analysis and failure models

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM