The VORTEIL project (‘Vertikale Oberflächenemitter für Robuste Temperaturstabile Effiziente Integrierte Lasersystems’ – Vertical Cavity Surface Emitters for Robust, Thermally Stable Efficient Integrated Laser Systems) is funded by the Federal Ministry of Education and Research to develop high-performance lasers based on VCSEL technology (cf. ill. 1). Lasers of this type can be used for such diverse application as a low-impact cleaning of monumental antique buildings or ignitions for large-scale combustion engines within the whole cylinder capacity at once.

The partners in the project consortium:

- Philips Photonics (Ulm and Aachen)

- Curamik (Eschenbach)

- Cicor (Radeberg)

- Clean Lasersysteme (Herzogenrath)

- Bosch (Stuttgart)

The Fraunhofer IZM’s activities in the project were dedicated to reducing thermal resistance and reduce thermomechanical stress of the laser pump modules by means of simple, but precise assembly techniques. For this purpose, established processes like soldering were optimized and innovative techniques like silver sintering developed further. This contributed to a substantial increase in the VCSEL arrays’ performance and life expectancy.

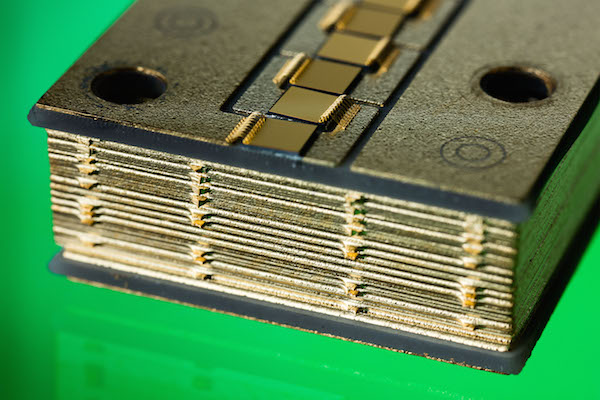

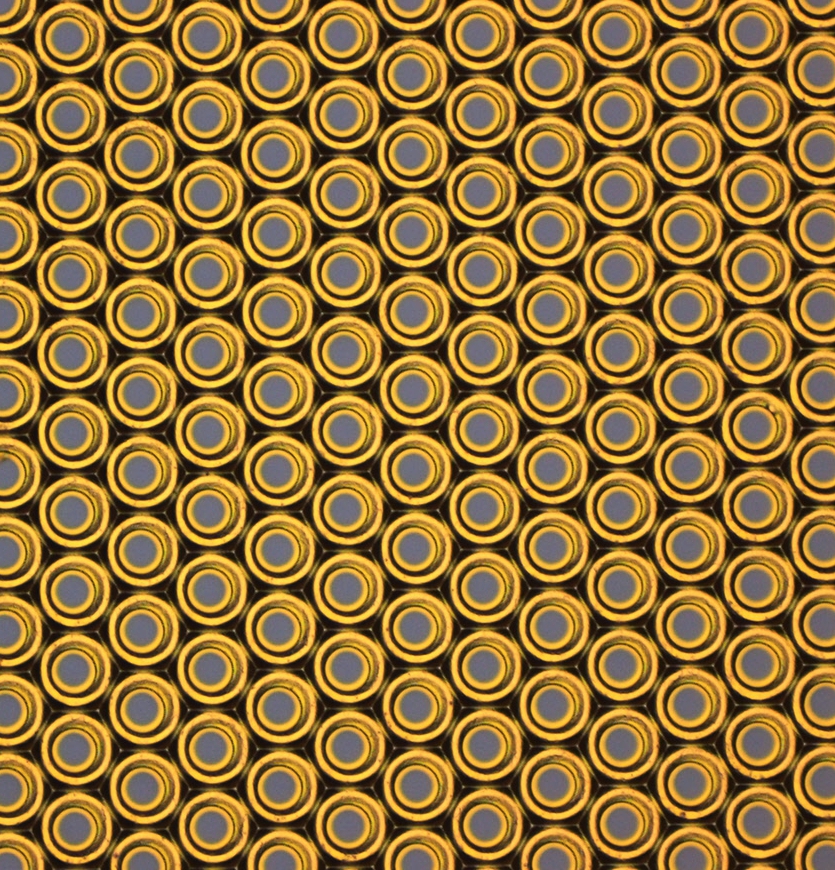

The successful scaling-up of the laser pump’s performance capacities allowed new types of applications, such as environmental friendly, low-impact surface cleaning. This was achieved by assembling multiple VCSELs on a densely packed array, with power supply and heat conduction structures integrated intelligently on the wafer level. The parallel manufacturing and quality monitoring, including the integration of micro-optics on the wafer level, and the use of highly robust components in terms of heat and pressure resistance enabled the designers to produce a very compact laser pump module. This required the electric and thermal bonding of the VCSEL arrays with a specialized substrate. Additionally, the cooling systems were improved substantially in terms of their thermal resistance through the contributions of the Rogers company. The mounting technologies used in the design, including SnAgCu and AuSn20 soldering and Ag sintering, made the assembly process simpler and faster.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM