Flip chip soldering on flexible substrates

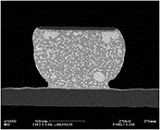

Flip chip soldering on flexible substrates is a reliable technology using standard equipment for pick and place and a subsequent reflow followed by underfilling. This technology is widely used for I/O-pitches down to 150µm.

For pick and place of flip chips as well as descrete components high precison fully automatic equipment is available (Datacon evo, Siemens Siplace X-Placer). To reduce production time the use of noflow underfiller, which is preapplied before reflow soldering, is feasible. Reflow processes in inert atmospheres can be performed using our flip chip and SMT-compatible line.

Different solder metallizations (SnCu, SnAgCu, AuSn, SnBi, PbSn) are available to meet product requirements, such as the temperature sensitivity of chips and substrates.

The flip chip on flex technology has proven to be a very reliable approach which is suitable for further miniaturisation of electronic products. Highest reliability results up to 10.000 thermal cycles have been verified e.g. with multichip flip chip modules for hearing aids

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM