LED design – assembly – characterisation

From the beginning of solid state lighting IZM was involved in LED development. Assembly processes for LEDs with highest power and power density were developed as well for LEDs in harsh environment or just to make mass production more reliable but cost-effective, too.

IZM has years of experience and is able to support already in the design phase to avoid known failures regarding thermal load, thermomechanical stress, colour quality and environmental aspects.

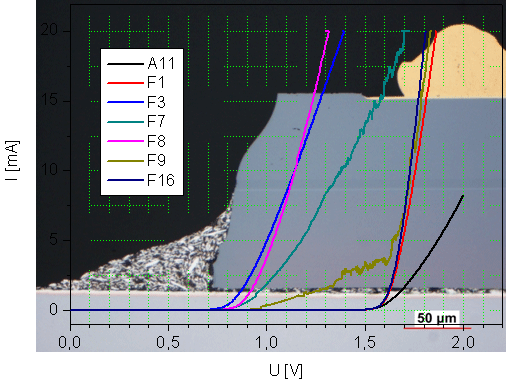

The developed LEDs and Modules, but also customer samples, can be characterized comprehensively. Electrical, thermal and optical analysis are possible.

If required the samples can be aged accelerated:

- constant Temperature with or without duty cycle

- slow and quick temperature cycling

- climate with defined temperature and humidity

- daylight and UV radiation

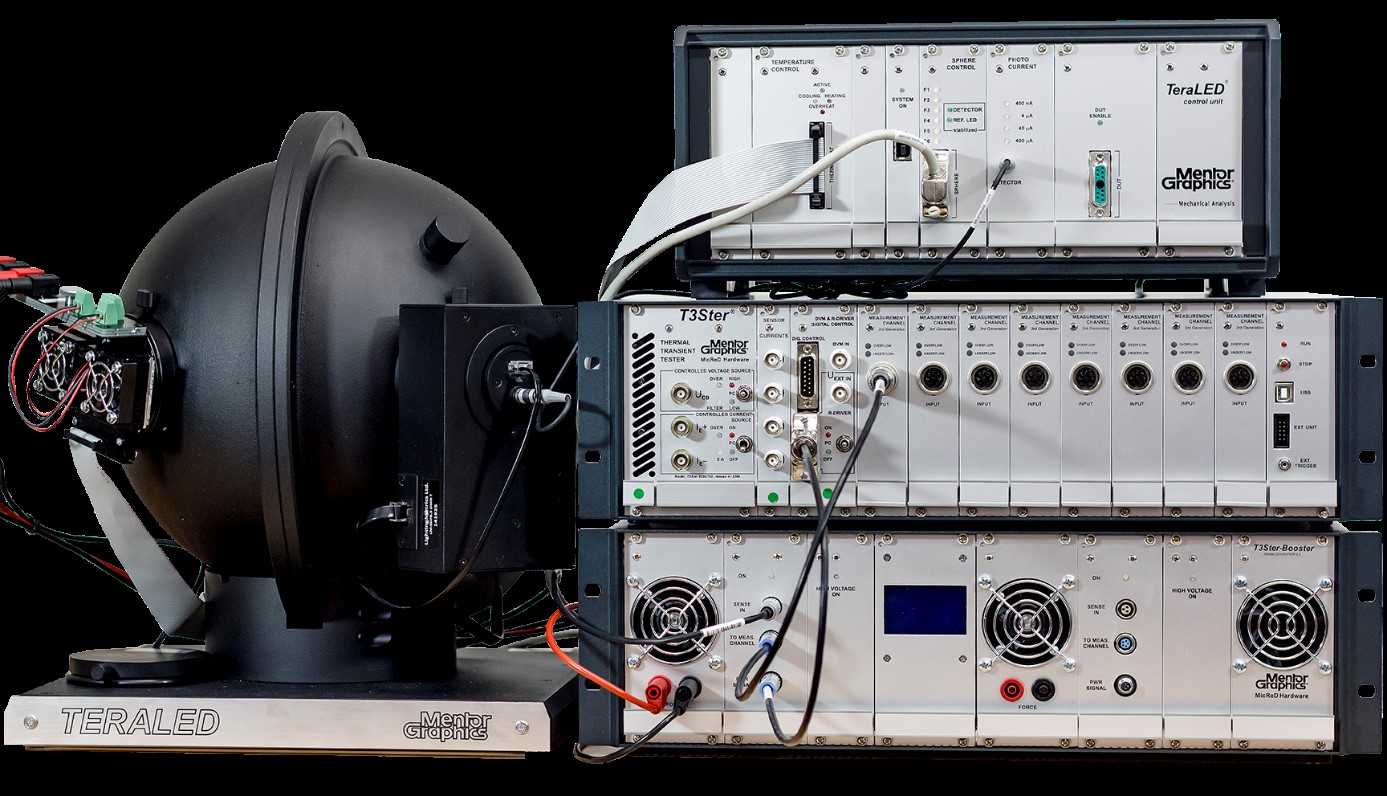

A TeraLED System with 20 independent sample positions is available for precise characterisation of the thermal path. As the emitted light is recorded simultaneous an absolute thermal resistance can be calculated. Aging of the samples can be monitored with or without duty cycles in a temperature range between 10 °C and 80 °C.

If during development or aging aberration from the specifications rise up or customers have failed modules, those can be analysed with our in-house equipment operated by well-educated staff:

- cross section with optical or SEM analysis

- chemical element analysis (EDX, ESCA, x-ray-fluorescence)

- x-ray microscopy

- focused ion beam (FIB)

- computer tomography (CT)

- scanning acoustic microscopy (SAM)

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM