Ultrathin flip chip assemblies

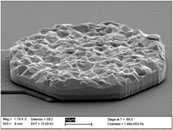

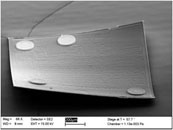

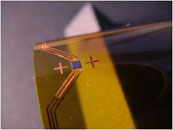

Nowadays, trends in miniaturization are going towards thin chip integration or 3D-packaging of thin modules. RFID applications are increasingly gaining interest, as the remaining chip thickness can be reduced to 50µm or even below. Identification labels with flip chip mounted IC’s on thin flexible antennas have reached an overall thickness of less than 50µm and may be integrated in other substrates, like paper or polycarbonate.

One assumption of ultrathin assemblies is the reduction of the bump height. Electroplating of CuSn or AuSn bump metallurgies can be used for small and thin bumps that require thermode soldering for flip chip mounting. Electroless NiAu bumps are a cost effective alternative for flip chip assemblies that are bonded using an adhesive. One benefit of the adhesive joining technology is the lower process temperature and hence a reduced thermal load of the substrate, resulting in lower package stress.

For thermode bonding, as well as adhesive joining, high precise flip chip bonders are available. Both technologies need experience and understanding regarding questions of bond tool geometries, non adhesive tool surfaces and consequent monitoring and control of the bonding parameters. In order to avoid the breaking of thin chips, the bonding force has to be optimized in terms of bonding results and carefulness.

Investigations on reliability of ultrathin assemblies soldered with CuSn metallurgy and adhesive bonded with commercial ACA show high stability in thermal cycling conditions.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM