Ultrathin solder interconnections

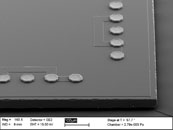

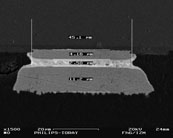

Today IC’s become more and more complex with increasing number of I/O’s at the same chip size or even on reduced chip sizes. This results in finer I/O-pitches. To avoid bridging of adjacent solder bumps during free reflow processes those wafer require thin electroplated solder caps instead of screen printed solder depots. Due to higher planarity requirements of thin solder caps those flip chips are soldered to flexible thin substrates by using a flip chip bonding machine. In order to achieve high reliable interconnections the flip chips have to be underfilled. This can be done either by applying a noflow-underfill before bonding, or with a capillary flow underfill after the bonding process. The reliability of different samples with 40µm pitch has successfully been tested. The thermode bonding technology was developed to produce high reliable flip chip interconnections on flexible thin substrates without solder masks in terms of reduced substrate costs.

Solder metallizations like SnCu, and AuSn are inhouse available. Especially in the case of thin soldered interconnections with ultrafine pitch chips, the interconnection metallurgy has a large impact on the reliability of the package. The knowledge of optimal combinations of solder material and substrate metallisation considering the handling of flexible substrates and soldering technology is essential for product design and realisation.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM