Waveguides made by ion exchange in thin glass foils

Optical waveguides can be integrated into glass substrates in a variety of ways. For low-loss optical waveguides, this is possible with an ion exchange technology originally developed in the 1970s and since intensively researched and refined for smaller formats in laboratory settings. Fraunhofer IZM began working with this ion exchange method in 2003. With its industry and research partners, the Institute has developed a process to apply it with commercial equipment and on large-format thin glass panels.

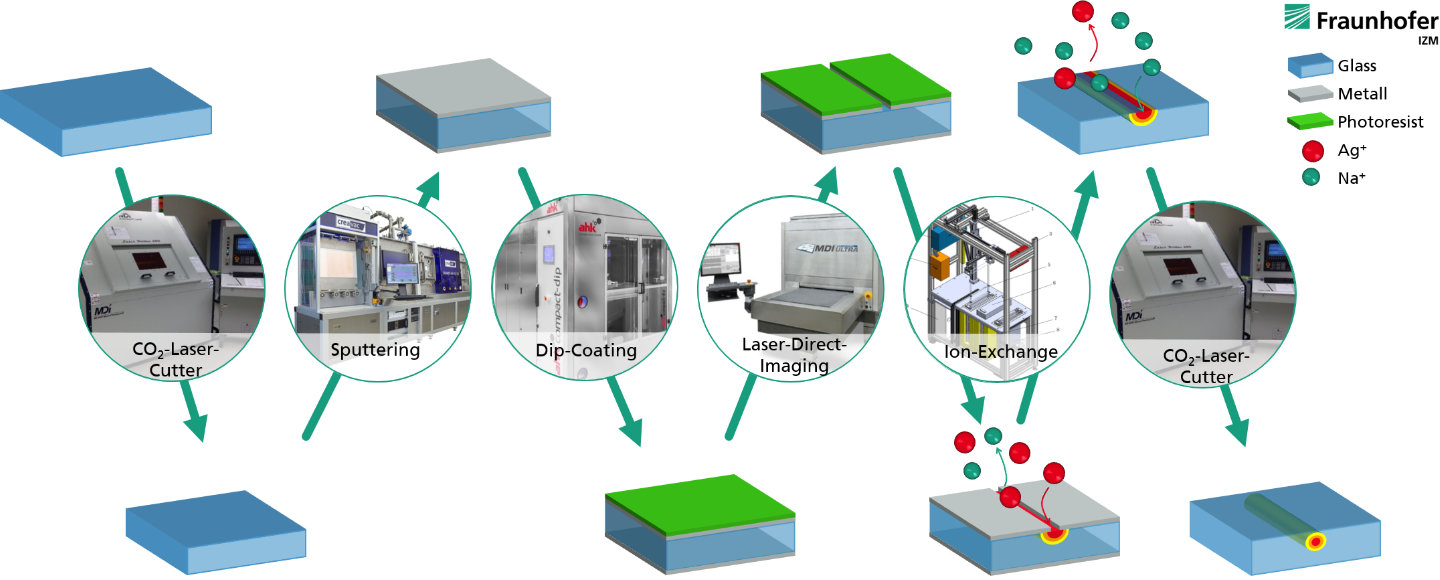

Seven distinct steps make up the essential process: The glass is first cut by a CO2 laser to the desired format and then metalized on both sides. A photoresist is applied to structure these layers by direct laser exposure, and the actual exchange of silver ions with the sodium ions within the glass is conducted by means of molten salt, creating a gradient diffraction profile that reaches its maximum near to the glass surface. A second ion exchange takes place after the diffusion mask is removed (leaving any labelling and guide marks), replacing the silver ions near the surface with sodium ions and diffusing the silver ions contained in the glass into deeper layers. This produces waveguides at several micrometers into the glass. In a final step, a CO2 laser is used to cut the panels to size, without the need to polish the resulting mirror surfaces. Depending on the waveguide layout, the end result is waveguides in place at the rim that can be coupled with fiber connectors.

Glass waveguide panels

- Glass: Schott D 263® T eco (others on request)

- Panel size: 440 x 305 mm2

- Thickness: 300 – 550 µm

Waveguide specifications

- Gradient index waveguides

- Low dispersion

- Buried waveguides

- Single-mode or multi-mode

- Propagation loss below 0.1 dB/cm

(λ = 850, 1,310 & 1,550 nm)

Laser cutting and structuring of glass

- Borosilicate glass, soda-lime glass (others on request)

- Glass size: up to 610 x 610 mm2

- Laser cutting of optical glass edge quality with high edge strength

- Laser structuring:

- Smallest structure size: 100 µm

- Structuring accuracy: ≤ 20 µm

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM