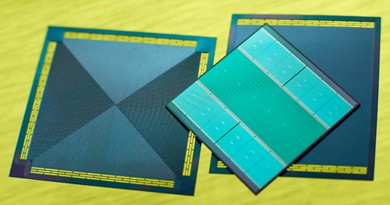

Interposer with liquid cooling

Results from the project CarrICool

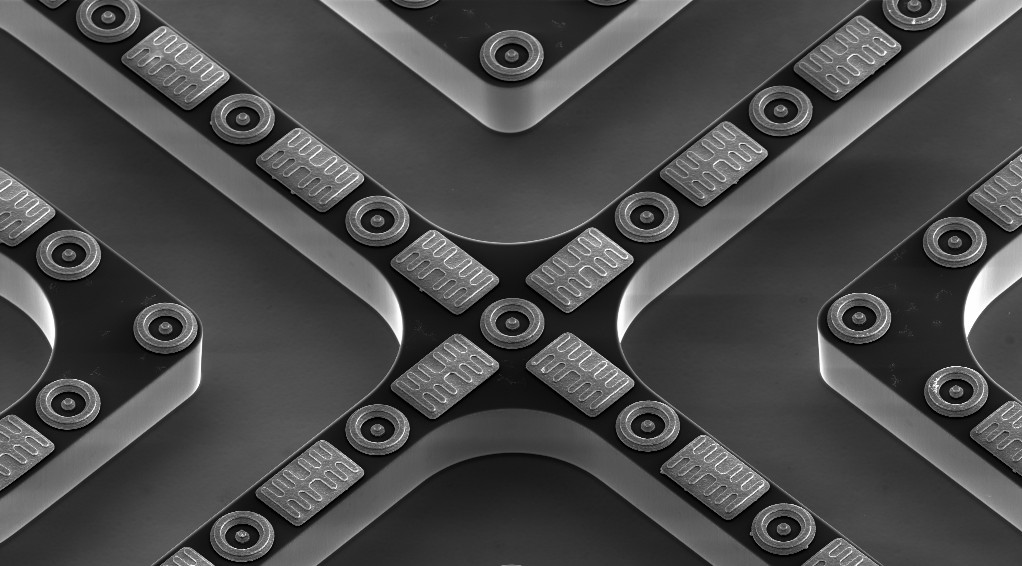

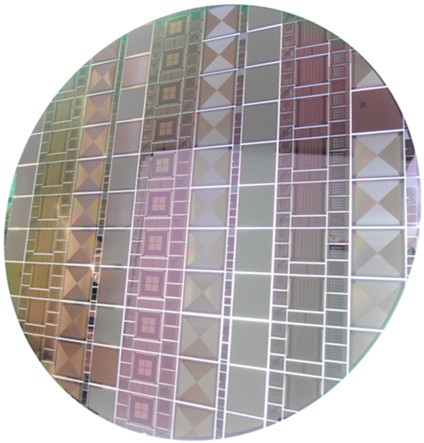

The maximum processor performance is limited by the heat removal efficiency. Therefore, a highly effective cooling technology as well as an innovative power management are the keys to increase the computing power. While air cooling is limited, a liquid cooling approach can meet these high requirements by targeting at a double-sided processor cooling. Within the project CarrICool, IZM-ASSID worked on the realization of a double-sided liquid cooling technology by innovatively integrating horizontal and vertical microfluidic channels. These micro channels are integrated in an electrically full functional interposer stack with Cu-TSVs in a waterproof manner. With this, for the first time, high performance processors can be additionally and effectively cooled from the bottom side, too. In combination with the integrated cooling plate on the top side of the processor, this double-sided cooling configuration allows the dissipation of 672 W heat from a 4 cm² sized processor surface with a maximum coolant temperature increase of only 60 °C. Compared to the performance of a common kitchen hotplate, this equals a forty times higher heating power when considering the same area size!

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM