6G Is Right around the Corner: With a Larger Selection of Materials to Enable High-Performance and Cost-Effective Hardware

The digital world is booming and has long since become part of everyday life in industry and society. More recent developments such as autonomous driving, telemedicine, but also private use require ever higher rates to transmit large amounts of data in real time. 6G should help with this: The aim is to transmit 1,000 GB/s and reduce latency to a tenth compared to 5G. At the current development stage, Fraunhofer IZM is working together with partners on researching a reliable hardware system for the mobile communications of tomorrow.

The global data pool continues to grow around the clock: It is predicted that up to 175 zettabytes, or 175 followed by 21 zeros, will be in circulation by 20251. This is not only

due to the increasingly video-heavy Internet use in the private sphere, but also because the economic trends toward Industry 4.0 and Smart Cities require ever higher data rates. The only way to deal with such huge amounts of data is to implement a new, reliable infrastructure—all the more so since the channel bandwidths of the first four generations of cellular network technology (1 to 4G) are almost fully utilized. This is the reason why higher frequencies above 6 GHz were set up when the 5th cellular network generation was introduced. However, even the 5G standard will not be sufficient to meet all the requirements of future applications. And this is the reason why research is already being done on 6G.

One aim of the new standard is to transmit data wirelessly in the Tbit/s range or to enable real-time communication. This can only be accomplished by using high bandwidths: Such bandwidths are available above 100 GHz. For instance, tests are currently being carried out in what is known as the D-band, i.e., the frequency range from 110 GHz to 170 GHz. Extensive research is needed before hardware modules can be used in this range: New modules such as package-integrated front-end components and antennas have to be developed, built, and tested.

One major problem encountered during the design of the new components is the high free-space path loss of the signals. This problem can be addressed by using architectures with hundreds of antennas per cellular base station with integrated beamforming (also known as massive MIMO architectures). In addition, the parasitic terahertz effects must be taken into account when planning the baseband. The consortium in the BMBF-funded 6GKom project has set itself the task to develop miniaturized, ultra-broadband modules at an early stage and thus establish a hardware foundation for the mobile communications of tomorrow. At the same time, innovative test methods and environments are simulated so that the D-band module can be tested, validated, and optimized after completion. In order to implement the specifications of the new generation in line with potential future applications, the cooperation partners coordinated their ideas in advance with an advisory board made up of representatives from a broad range of industries, including the chip, printed circuit board, material manufacturing, telecommunications, aviation, and agricultural machinery industries.

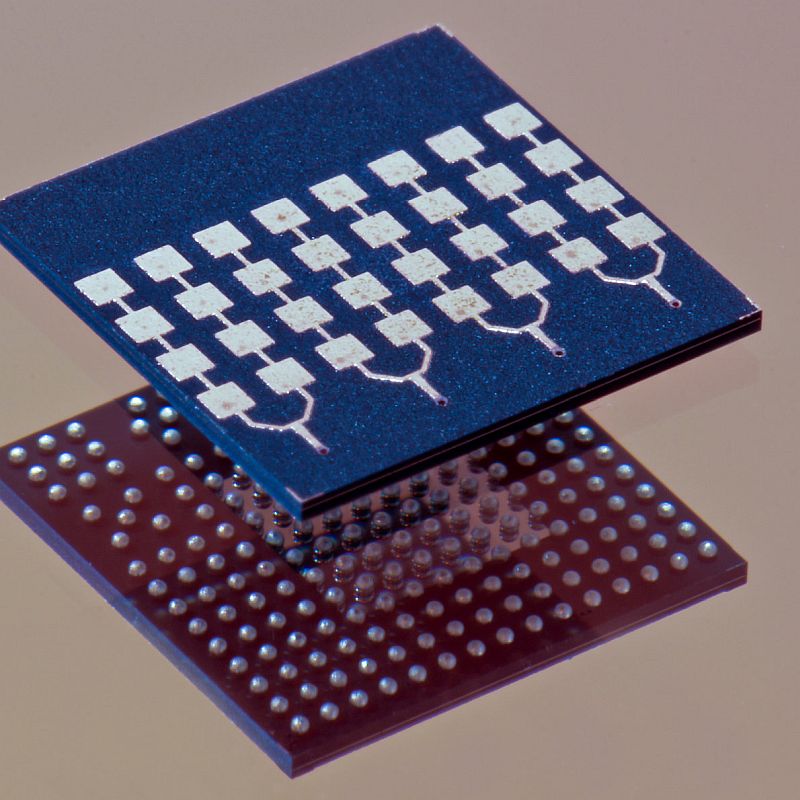

Fraunhofer IZM coordinates the project and is responsible for the development and construction of an active 6G antenna as well as the design and packaging of the entire module. The key feature of the assembly is the complex antenna design: In order to avoid losses during transmission, the chip must be installed as close as possible to the antenna. This approach and the high degree of miniaturization of the modules result in the creation of very high-density structures, which, in turn, requires specific measures to ensure reliable heat dissipation and signal integrity. After weighing up all requirements, the team of experts led by Michael Kaiser and Prof. Ivan Ndip decided to use wafer-level processes for the design: This ensures very low path losses despite the extremely fine structures and also leaves the rear side of the package exposed, thus enabling the direct connection to a heat sink at this point.

In comparison to alternative solutions—in which the antenna and control chip are manufactured as a single component, i.e., where both are made of silicon—the 6GKom team opts in favor of building a package-integrated antenna: In this way, it is no longer necessary to use silicon as the base material for antenna design. This freedom with regard to material selection enables better performance in terms of bandwidth and antenna gain. Consequently, the packaging materials can be selected specifically to reduce losses, which means that the energy is emitted efficiently and not dissipated. Finally, placement on the chip would increase the chip’s area significantly, which is very expensive. This is why the researchers integrate the antennas outside of the chip. At the end of the project, the team will present a final demonstration unit, which will be used for wireless communication between the D-band modules in a laboratory setup.

During the first technological phase, the researchers used simulations and prepared test structures to check the suitability of the basic building blocks of the package, such as lines, line transitions, and antennas for the D-band. The antennas in the planned integration platform achieve bandwidths of around 10 GHz. Finally, terabit data rates can be achieved by bundling multiple channels. After the active components for controlling the antenna’s emission pattern have been manufactured by the project partners, the experts from Fraunhofer IZM will start working on the integration into a complete module. The aim is to create a powerful and reliable hardware system for frequencies above 100 GHz in close cooperation between the partners. The ForMikro - 6GKom project is funded by the Federal Ministry of Education and Research (BMBF) with 2.86 million euros under the funding code: 16ES1104K. In addition to Fraunhofer IZM, the research partners include TU Berlin, TU Dresden, the University of Ulm, and Leibniz IHP. The Industry Advisory Board consists of Airbus SE ALCAN Systems GmbH, Ansys, CONTAG AG, Continental AG, Creonic GmbH, Ericsson, Globalfoundries Inc., Heraeus Group, Infineon Technologies AG, Isola GmbH, John Deere, National Instruments Dresden, Rohde & Schwarz, Schott AG, TE Connectivity, and Vodafone GmbH.

1 https://www.bmwk.de/Redaktion/DE/Schlaglichter-der-Wirtschaftspolitik/2020/09/kapitel-1-7-auf-einen-blick.html

(Text: Olga Putsykina)

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM