Are our electronics watertight?

The makers of electronic equipment built into cars or industrial machines know the problem only too well: Electronics fail earlier than they should, because humidity seeps into their sealed housings. Reliability tests are conducted to prevent that from happening. Now, researchers at Fraunhofer IZM teamed up with the European Center for Power Electronics (ECPE) to learn more about the climatic conditions inside electronic systems. They used a battery of simulations and analytical tests to include environmental factors already from the initial choices for case designs and avoid costly later failure analyses.

Electronic components have to be protected from humidity to work properly. Protective cases and housings are needed that keep the sensitive electronics dry and safe and make sure that systems like car engines or industrial machines last and work properly for many years. Depending on the application in question, these cases have to contend with different environmental conditions and changing climates. The temperatures in the system will differ because of different electronic components having different levels of thermal dissipation. The end result: A single sealed system will have several microclimates on board. But with a smart layout of the sensitive parts, a functioning electronic system can be designed that keeps these different microclimates in just the right balance that is favorable to the system as a whole.

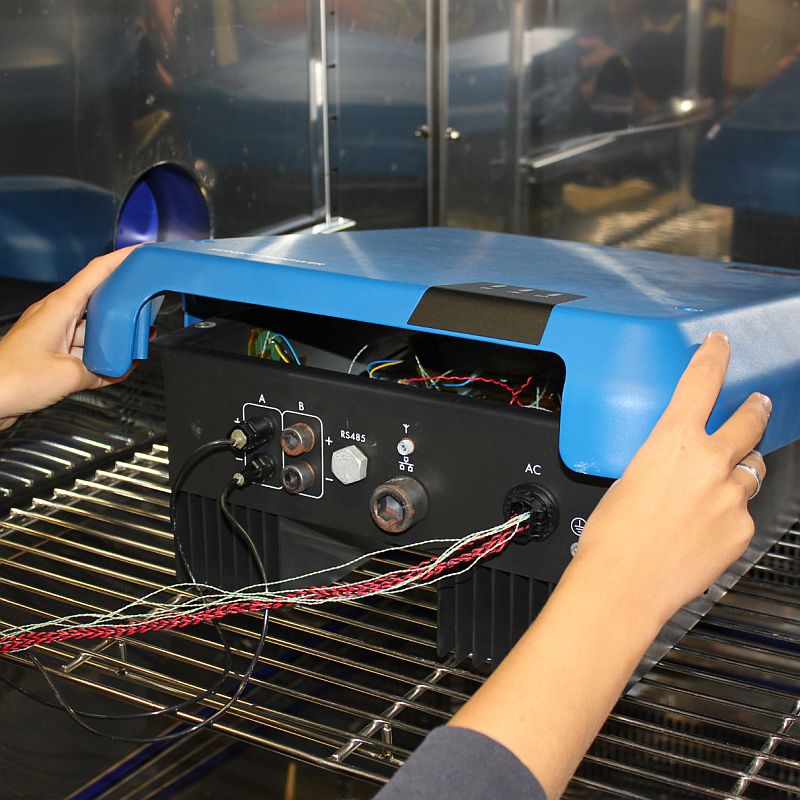

How climatic conditions differ during operation even in a sealed case could now be proven beyond doubt as part of the successful RoDosH (Relevance of Diffusion of Humidity in sealed Housings) project, using the case of a photovoltaic inverter made by SMA. Such inverters turn the solar energy captured and turned into electricity by PV cells into an electric current that can be fed into the public grid. The Environmental & Reliability Engineering unit at the Fraunhofer Institute for Reliability and MicroIntegration IZM has 30 years of experience with reliability simulations and assessments. This experience and methodological knowhow were used to put an inverter case through its paces in four separate trial stages. The unique feature of this process: The sheer range of competence assembled on the team. Because it needs many years of experience in not one, but several fields to characterize and simulate all of the materials meaningfully - experience that the team possesses from its many research and commercial projects. On top of the many use cases that the researchers could draw on from prior experience and past projects, they have access to cutting-edge equipment, including conventional climate chambers and dedicated drop test machines as well as highly specialized measuring devices like the so-called thermo-gravitation and sorption analyzer or TGA-SA.

Characterizing and modeling sealing designs

Before generic or specialized reliability trials are launched, Fraunhofer IZM would usually begin with load or mission profiles. For the case of the PV inverter, two separate load profiles were prepared to show in detail how climatic conditions at different geographic locales will affect the systems. The experts in Berlin cast their nets wide and decided on profiles that match the tough climates that PV systems would have to deal with in e.g. Kuala Lumpur or Mumbai. Weather data was drawn from public sources to understand the specific challenges, like very high average temperatures over the course of the year or extreme humidity. For a contrast, profiles for more moderate climes were chosen, using weather data from Kassel in Germany, Beijing, and Tromsø.

In a second step, the researchers put the PV inverter’s casing through several rounds of tests to monitor temperatures inside and around the system. Alongside traditional climate chambers, they use specialized devices for material characterization, like the TGA-SA that can catch even tiny accumulations of humidity by carefully tracking minute changes in weight over a long time. In order to understand the system’s internal climate as contrasted with the surrounding environment and to draw conclusions about how well sealed it is and how individual materials behave, the climate experts rely on a battery of diffusion coefficients. These determine the time it takes for humidity to get into or out from a given material.

Water vapor pressure, air humidity, and other indicators are modeled in a third step, which uses the ANSYS® software for a combined simulation of temperatures and concentration fields. It allows the researchers to show how relative humidity and local temperatures change throughout the system. More simulations show condensation risks by combining the material properties taken from step two and a standard day-night cycle to understand the impacts of normal or longer stay periods or gradients in temperature.

Understanding impacts on a system’s life expectancy

In the fourth step, the testing and simulation experts try to understand how accumulated humidity can affect a system. In the case of the PV inverter, the culprit is often the slight differences in temperatures, which can lead to localized losses and, in turn, to different levels of humidity throughout the system.

Over the 18 months of its duration, the project showed how close the model came to simulating real-life behavior. The test kit developed at Fraunhofer IZM allows a reliable insight into how changes to the layout or materials affect the performance of casings or electronic components. It can be put to use at an early stage in a system’s design and development to analyze, assess, and characterize the effects on systems and casings and inform choices in the process going forward. For the makers of electronic equipment, this represents a game changer, as it turns the old approach on its head: In the past, insights about why electronics fail could only be gleaned from experience, that is, from systems that have already been fully developed and actually failed during use. The experts at Fraunhofer IZM have put an end to this and the ability to simulate and test systems before they are released means that electronics and their casings will become safer, more reliable, and more durable overall.

You can find out more about the groups' scope of services here.

This work was funded by the ECPE Joint Research Programme.

(Text: Niklas Goll)

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM