Project NaLoSysPro

What really happens on the assembly line? High-precision localization promises more transparency!

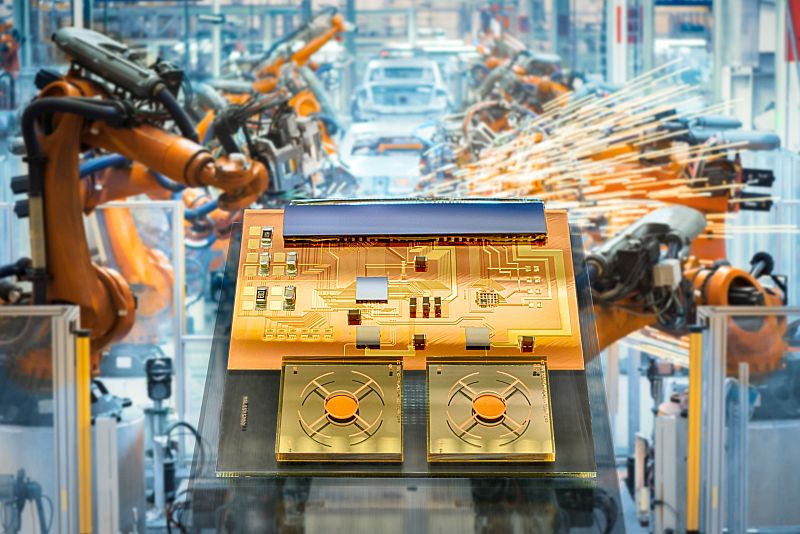

A miniature transponder helps localize tools at manual assembly stations. Fraunhofer IZM has developed a specialized transponder in the joint NaLoSysPro project to track and record safety-critical assembly tasks in industry with precise location data. The project was completed in 2018, and the innovative transponder is showcasing the capabilities of Fraunhofer IZM’s Wafer Level System Integration team to the manufacturing community.

Anybody who has ever used a screwdriver knows: The end result depends on the right angle of attack and the right torque. This applies even more when people’s lives are at stake – for instance when joining parts on a car assembly line. This is why the NaLoSysPro project was launched to make manual assembly work more precise and more reliable.

NaLoSysPro stands for Near-Field Localization of Systems on Production Lines, or put more simply: Tracking where exactly a tool is and what it does on the assembly line. The position data is recorded with other parameters that might be relevant for a well-executed joint, such as the applied torque. Each step in the assembly process creates a specific data log that helps evaluate the accuracy of the process and trace any potential deviations.

This is achieved with four fixed radar emitters and a mobile transponder on the tool itself. The transport sends signals back to the radar units, where complex algorithms help pinpoint the exact location of the tool. The miniature transponder itself was developed and brought to life by the Fraunhofer Institute for Reliability and Microintegration IZM. The project brought together and refined several of the core competences of Fraunhofer IZM for its specific application, such as the bumping technology for individual chips – a rare niche technology usually reserved to R&D projects where entire silicon wafers would not be an (economical or otherwise) option. The project has also created new insights into transponder technology and antenna integration in radar systems.

With funding support from the German Ministry of Education and Research, Fraunhofer IZM and its eight project partners completed the NaLoSysPro project in 2018. Under the careful guidance of Thomas Fritzsch and Jürgen Wolf, Fraunhofer IZM designed the miniature transponder for on-tool mounting.

On the 10th and 11th April, Thomas Fritzsch will introduce the NaLoSysPro-transponder to the wider public at the Smart System Integration SSI expo at the Fraunhofer IZM booth H08 in Barcelona. From there it will continue its journey to the SMT connect and Sensor&Test in Mai and June 2019 trade fairs.

Last modified:

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM