SiCefficient: increase of efficiency and range

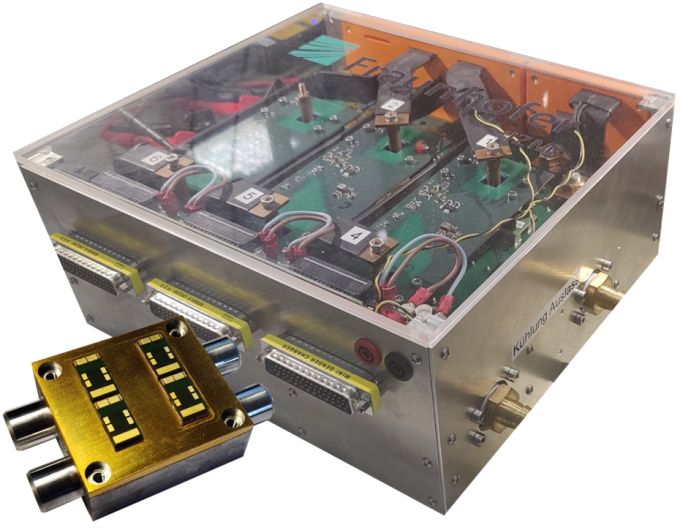

The use of SiC semiconductors in drive inverters is becoming increasingly popular. SiC offers the possibility of increasing the power density and efficiency in the system through lower switching and conduction losses compared to silicon FETs. The converter built at Fraunhofer was realised in a 6-phase topology. With the appropriate electric motor, this results in several advantages for the electric power train. On the one hand, this creates redundancy: if one phase fails, an emergency operation is possible with the remaining 3-phase system. On the other hand, a reduction of the electromagnetic interference levels and bearing currents generated by common-mode interference by 30 dB can be achieved by driving the two-phase systems in phase opposition. On the one hand, this would make it possible to dispense with shielding, and on the other hand, the reduction of the bearing currents leads to less wear and less effort to insulate the bearings of the e-machine.

In the SiCefficient project, a design is realised with which the SiC MOSFETs are operated at their electrical limits. On the one hand, this is realised by an optimised thermal interface. Here, the semiconductors are connected directly to the heat sink via a sintered silver connection. On the other hand, special emphasis is placed on the low-inductance connection of the DC link capacitor to reduce switching losses. A commutation cell inductance of < 2.4 nH with two parallel semiconductors and a particularly powerful driver output stage enable fast switching with voltage gradients of up to 60kV/µs.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM