High-performance power electronics

System design | Simulation | Embedding technologies for SiC and GaN semiconductors

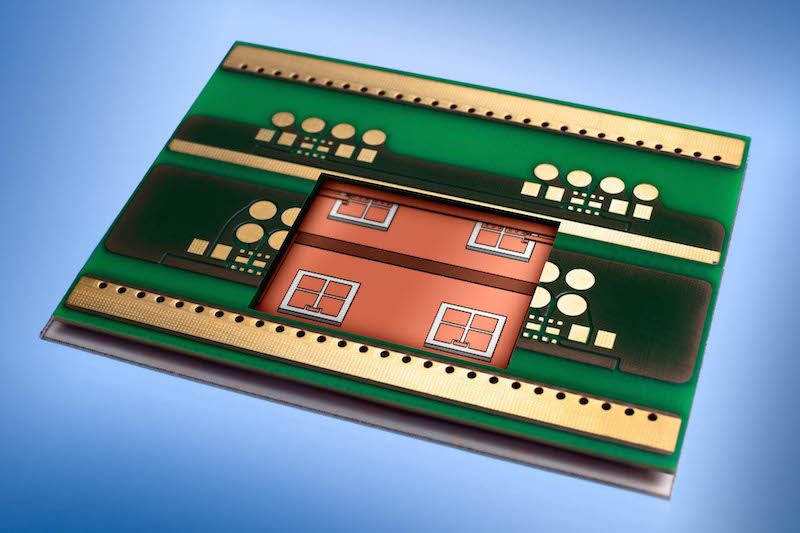

Semiconductor components made of silicon carbide (SiC) and gallium nitride (GaN) offer the advantage of high switching speeds. Power semiconductors are used in a multitude of inverter systems – for example, in traction inverters for electric vehicles.

The researchers at Fraunhofer IZM have many years of experience in both processing with embedding circuit board technology and the design and customized development of power electronics modules with power semiconductors based on silicon carbide (SiC), gallium nitride (GaN) and silicon (Si).

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM