High-Speed Prototyping with Stereolithography 3D-Printing in Optical Packaging and Interconnection Technology

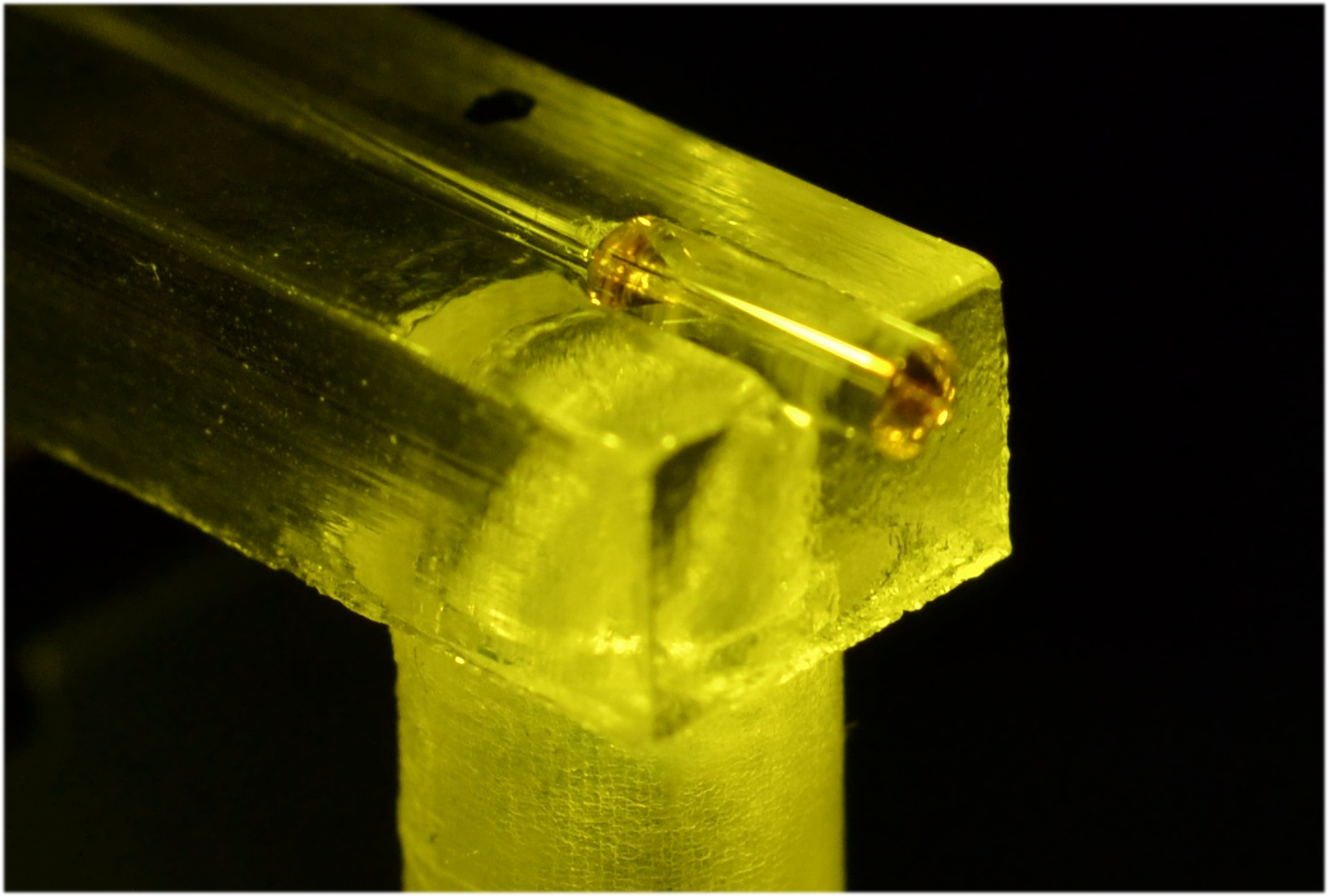

Stereolithography or SLA is a 3D-printing technology used to turn polymer-based functional materials into precisely engineered parts or tools.

The SLA 3D-printing technique employed at Fraunhofer IZM can achieve layers of between 0.025 to 0.1 mm thickness (depending on the materials used). The base materials are made from a photopolymer resin that is hardened by exposure to a laser beam a mere 0.14 mm wide. The specific materials are chosen for their properties to match the intended application:

- Transparent

- Bio-compatible

- Heat resistant

- Mechanically durable (rigidity, tensile strength, suitability for e-modules etc.)

There is a wide range of possible use cases, as transparent materials are e.g. a preferred choice for optical or fluidic applications. The range of materials and the high speed of the process make the technology an ideal option for fast prototyping an almost any area of application.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM