The innovative dosing technology can handle liquids with a vast range of viscosities (from 200 mPa*s to 10000 mPa*s) for a flexible choice of materials.

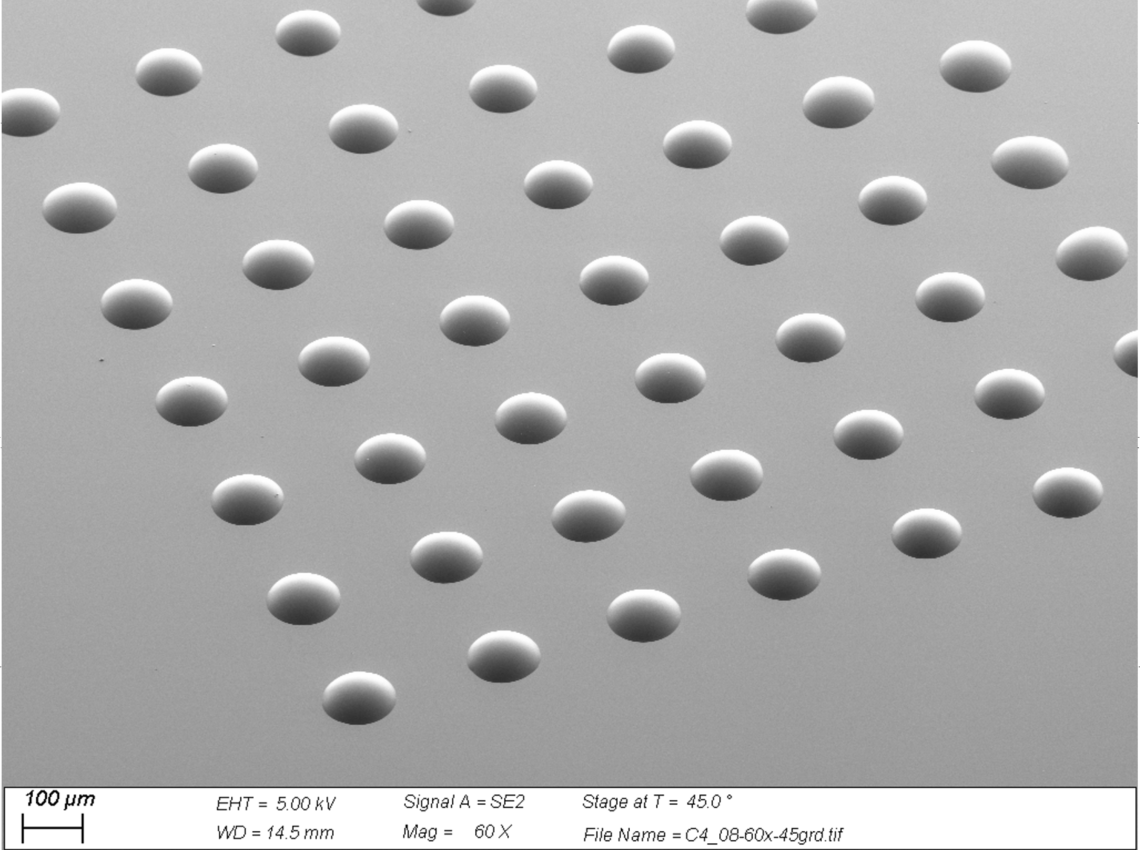

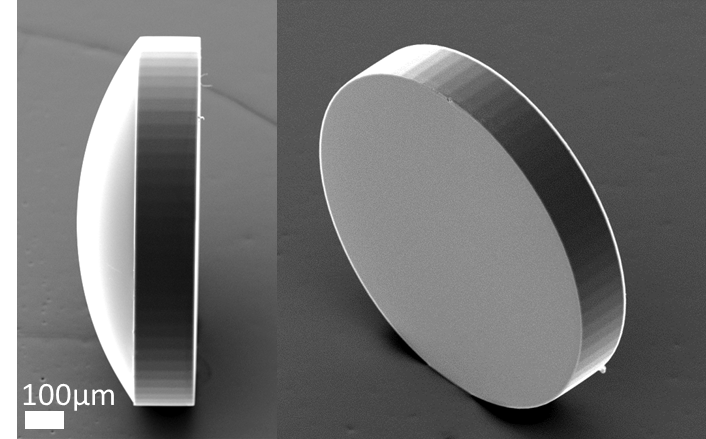

The great versatility of the picolitre dosing system gives clients a choice of additive or moulding processes to create microoptical structures or apply biochemical analytes to substrates. Image 1 shows a 7x7 microlens array, applied to a glass surface in a highly precise touchless process. The system’s feed head can also be used to fill PDMS cavities to produce custom microlenses.

The proven compatibility of the picolitre dispensing system makes it an ideal choice for placing, bonding and aligning micro-optical components in photonic assemblies.

These technological capabilities combined with our long-standing expertise offers access to innovative, but reliable processing methods for optical packaging and interconnection technology, designed and customized in cooperation with our partners.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM