Conformable electronics

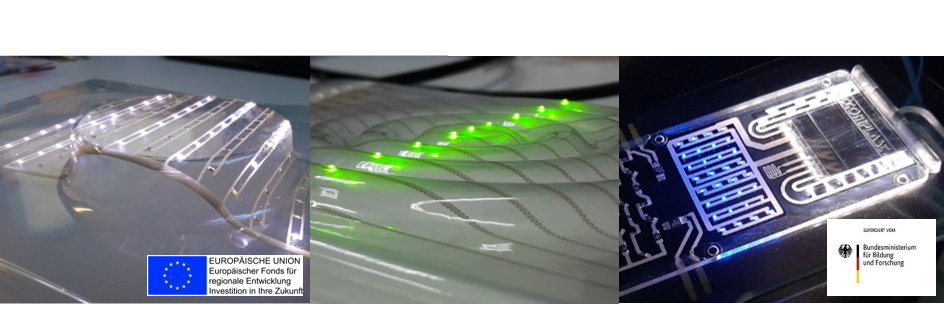

Rigid and flexible printed circuit boards are well-established and widely used circuit carriers for electronic assemblies. New product concepts require electronic systems that can be applied or integrated onto or into three-dimensionally shaped freeform surfaces: known as Conformable Electronics. In such products, the weight and volume of the electronic system can be reduced. They also enable systemic changes by providing structural elements and surfaces with electronic functionalities through integrated sensors and actuators.

An important aspect for the market acceptance of Conformable Electronics is the manufacturing process. The term "conformable" implies that it primarily involves malleable electronics, i.e., electronics that are not initially built in a three-dimensional manner (an approach pursued, for example, in MID technology). When building Conformable Electronics, established and cost-effective two-dimensional process technologies are largely used for constructing the circuit carrier (printed circuit board) and for component assembly. This allows Conformable Electronics to be manufactured like conventional electronic systems and their properties beyond rigid and flexible circuit boards only emerge in the final fabrication or application step, which involves deformation (vacuum thermoforming or high-pressure thermoforming).

At Fraunhofer IZM, the combination of design, materials, and process technologies for various aspects of Conformable Electronics is being developed. The manufacturing and product concepts include electronic systems on polymeric or textile circuit carriers that can stretch once or multiple times, allowing seamless coverage of three-dimensional freeform surfaces. The conductive traces consist of specially designed copper structures or printed stretchable pastes. The interactions between design, specific construction, and highly pronounced deformation are the subject of ongoing research and development efforts.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM