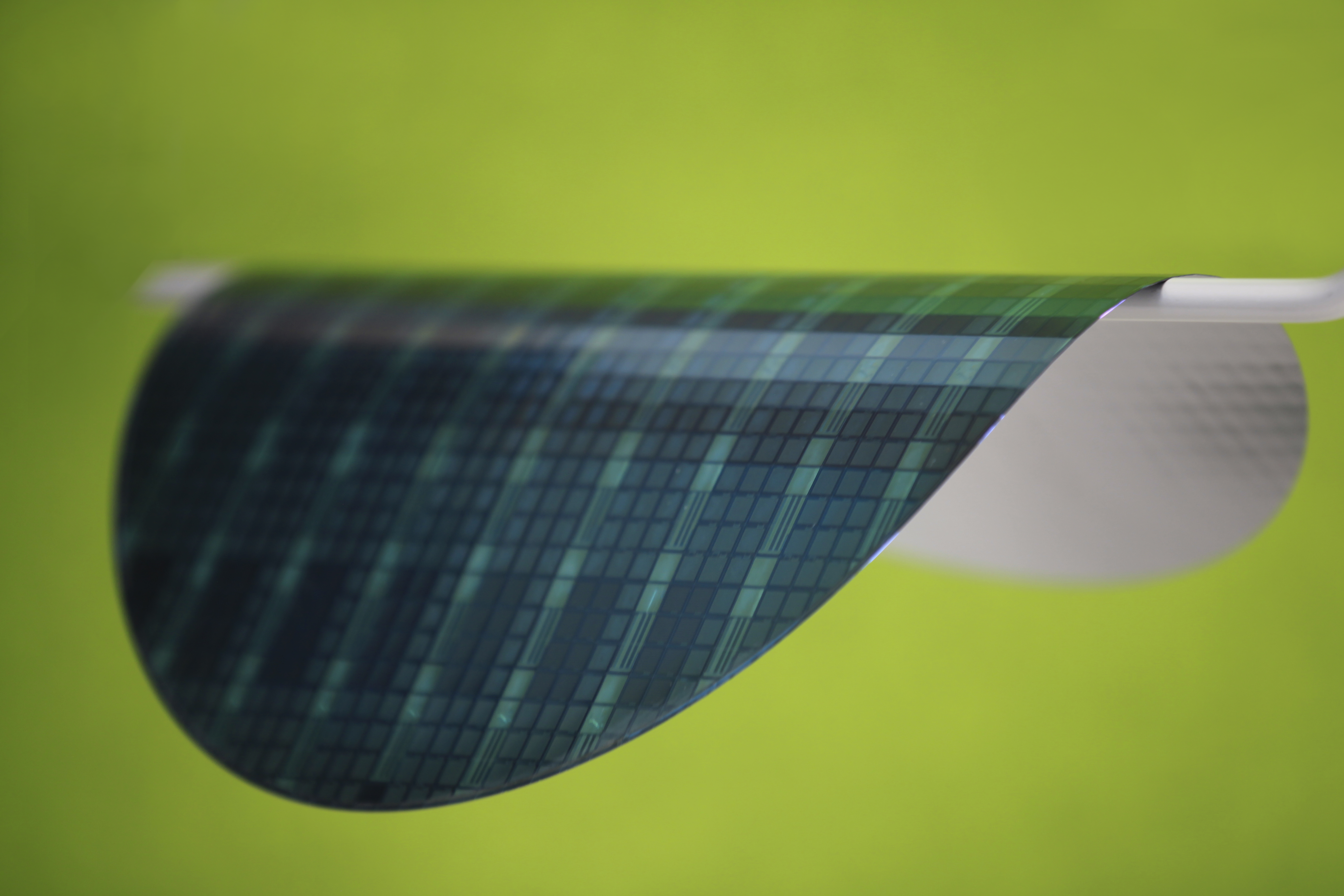

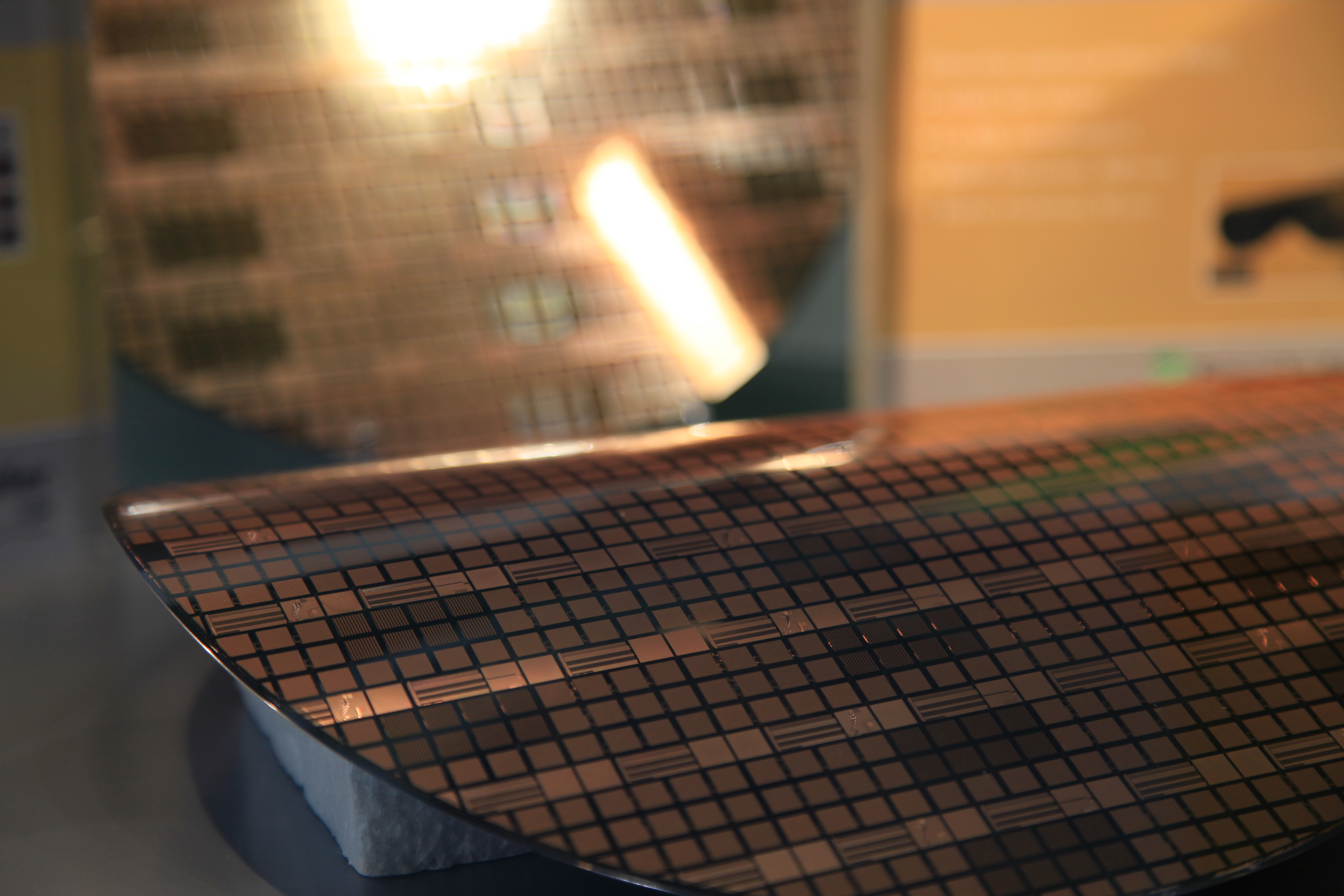

- ASSID Test Wafer

- Cu RDL metallization

- Wafer diameter: 300 mm

- Wafer thickness: 50 µm

Enhanced dicing technologies using low-k materials, small dicing strets (<40 µm) and reduced mechanical edge and corner damage to wafer frontside and backside

- Wafer Singulation - Mechanical Blade Dicing: Mechanical blade dicing of 300 (200) mm single wafer ·(50 – 775µm thickness)

- Wafer Singulation - Laser Grooving: ·Dicing technology: Q-switch pulsed UV-Laser (50 kHz) with wave length of 355nm

- Wafer Singulation - Laser Stealth Dicing: Applicable to higher doped wafers (> 0,02 Ohm*cm)

- Wafer Edge Trimming

Further Services

Back Grinding Tape Lamination

- Back Grinding (BG) Tape Lamination of 300 (200) mm UV and Non-UV tapes

Wafer Backgrinding

- Back grinding technologies: Grinding before Dicing (GBD), Dicing before Grinding (DBG), 300 TAIKO Dicing

- Wafer Backgrinding/Polish of 300 (200) mm single wafers

- Wafer Backgrinding/Polish of 300 (200)mm temporary bonded wafer stacks

Wafer Mounting, Peeling, Exposure

- Inline wafer mounting and BG tape peeling of 300 (200) mm single wafers on 300 (200) mm Film Frame Carrier (Disco type, metal or plastic film frame carrier)

- Application of various UV- and Non-UV dicing tapes including DAF-tape

- Inline exposure of UV-tapes

- Packing and transportation of Film Frame Carrier in 300 (200) mm Film Frame Shipper

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM