Online event | Expert Session Series / April 20, 2021, 4:00 pm - 4:45 pm CET

Highly reliable Solder and Sintering Technologies

Electronic packaging and assembly is the basic technology to link the small dimensions of the IC to an interconnecting substrate - usually the Printed Circuit Board / Printed Wiring Board (PCB / PWB) or a Multi-layer Ceramic (MLC) such as "Low Temperature Co-Fired Ceramics" (LTCC).

New applications with their expanding performance and functionality in conjunction with new device technologies are pushing the requirements and innovation for electronic packaging. The metal-metal interconnect can be made by soldering, welding or gluing, all are well-established processes at Fraunhofer IZM. The reliability of electronics will be further pushed to a higher degree in the future. Therefore, reliability standards will see failure rates expressed as failures per billion parts rather than per million parts as is cur-rently the case.

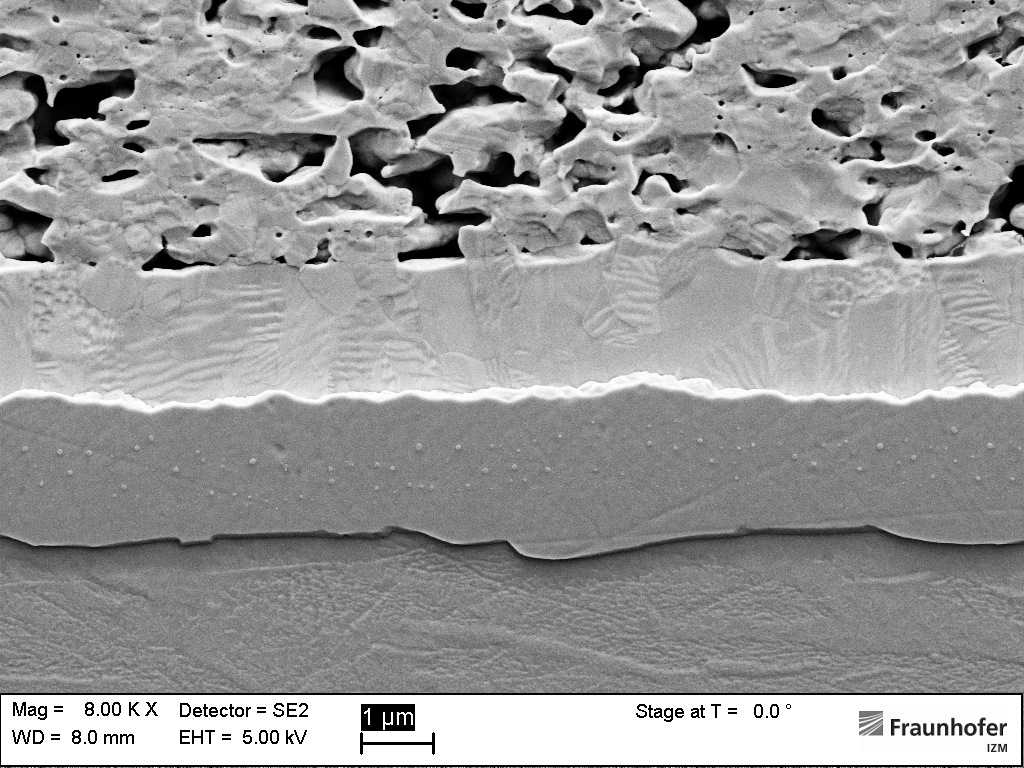

Silver and copper sintering are new die attach technologies which result in a higher life time of the whole power package. Ag and Cu as ductile metals have a high melting point and a very high thermal conductivity. Therefore, especially for a higher performance and higher operating temperatures Ag and Cu sinter joints are very promising.

There is another new joining technology currently under development which is referred to as “transient liquid phase soldering/bonding” (TLPS or TLPB). The idea behind this technology is that the Sn-based solder is transformed in intermetallic phases which have a higher melting temperature than the solder alloy has had before the joining has been carried out. The higher melting point is necessary to withstand higher operating temper-atures or for withstanding subsequent soldering processes during manufacturing.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM