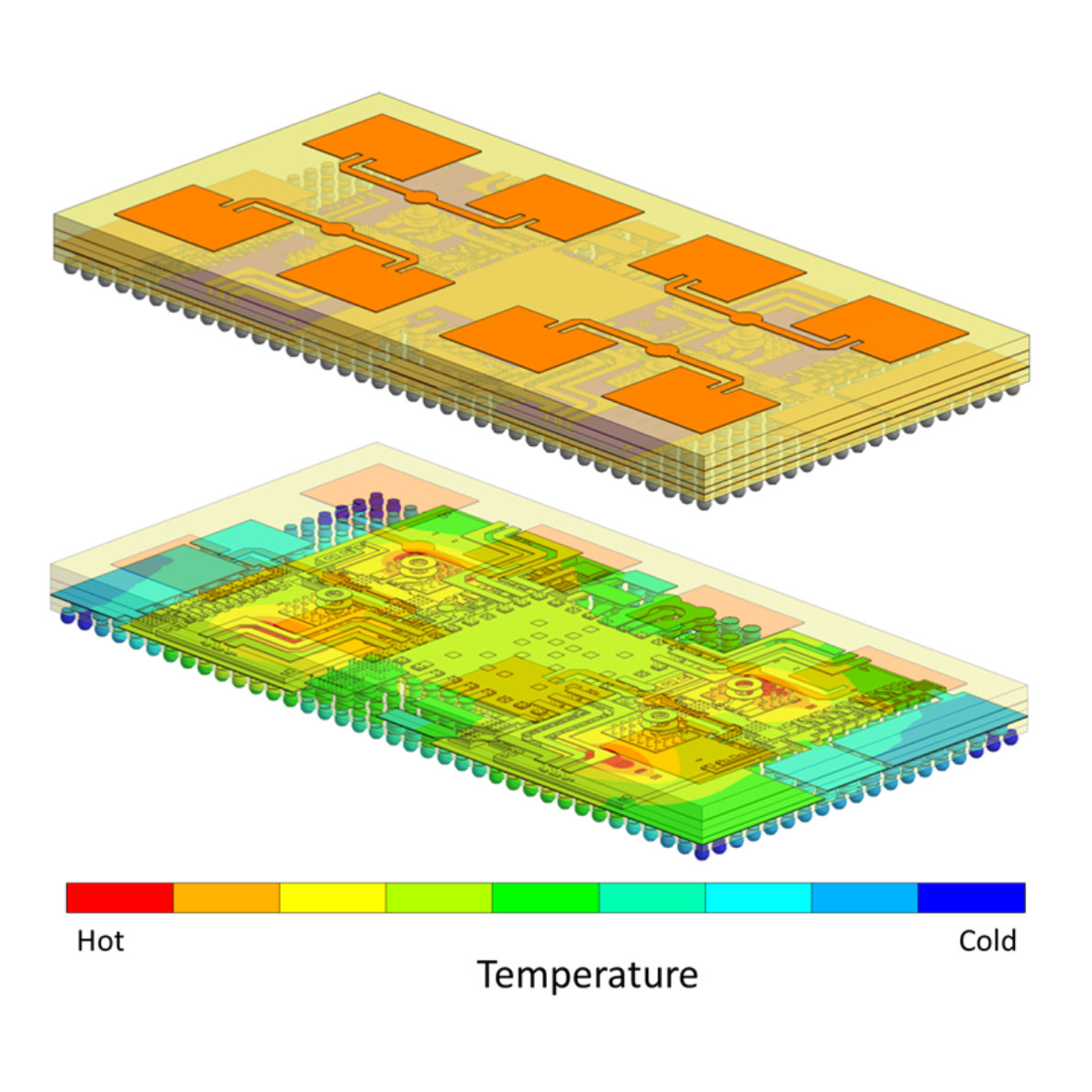

Thermal management

Current trends in vehicle electrification, miniaturization and increased switching frequencies mean that a sophisticated thermal management is required to ensure reliable operation even when high power dissipation, high heat flux densities and high ambient temperatures are encountered. By means of numerical simulation, the thermal behavior can be analyzed in a cost-effective and versatile way.

Thermal management topics include:

- Radar and antenna modules: Caused by the increasing transmission bandwidth the power dissipation increases as well. Therefore, it must be clarified which packaging and interconnection technologies are to be used in order to be able to reliably dissipate the heat without influencing the switching behavior.

- Power modules: How should the module be contacted to a heat sink so that the high power dissipations are efficiently dissipated, while at the same time ensuring electrical insulation?

- Smart Power Modules: How can the thermal resistance of molded packages be minimized so that it can operate at elevated ambient temperatures?

- LED: How can the occurring heat be spread as well as possible and how should the interconnection between LED and heat sink be realized?

Relevant material data for thermal management, such as thermal conductivity and specific heat capacity, can be determined at Fraunhofer IZM. Thermal Interface Materials (TIM) are of particular importance here, of which their properties can be measured as a function of contact force and displacement.

Either static or transient thermal simulation can be performed, whereas for the later the heat capacity of the materials during fast switching operations is being taken into account. The power losses occurring in the package can also be calculated by electrical- thermal multiphysics simulations.

Sensitivity analysis and optimizations are efficiently calculated and evaluated using ANSYS OptiSLang. This allows the selection of an optimal geometry and materials with respect to the thermal behavior.

In addition to the calculation of heat conduction, cooling boundary conditions must also be considered. ANSYS ICEPAK/CFX is used to simulate and optimize water and air cooling for individual packages and housings.

IR thermography can be used to experimentally characterize the static and transient behavior of products and materials and to directly verify the thermal resistance (Rth) or thermal impedance (Zth).

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM