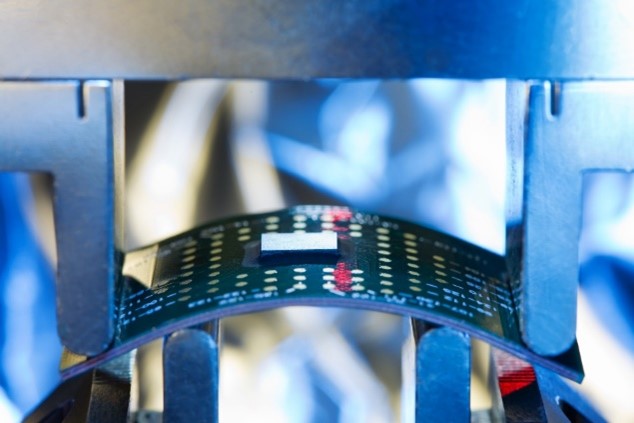

Mechanical and thermal characterisation of materials

Precise materials data form the basis for reliable products. Understanding the properties of materials and knowledge of the relationship between production processes, stresses and failure mechanisms enables the improvement of processes and products.

Materials can be characterised individually or in their application.

The measurements can also be carried out at various levels of environmental conditions (e.g. humidity and temperature), in order to determine the material behaviour for the process or application conditions.

For reliability assessments with FEM simulations, the parameters can be used to calibrate material models.

Key material characteristics, which can be analysed in our Lab are:

- Mechanical parameters (e.g.Young’s-modulus, Yield stress, strain of break etc.) in wide range of sample geometries (macroscopic and microscopic) under static and dynamic loading

- Determination of Poisson’s ratio for material samples with optical deformation analysis

- Elastic, plastic, viscoelastic, hyperelastic properties

- Determining temperature- and time-dependent behaviour of adhesives, polymers, moulding compounds (Relaxation/Retardation)

- Investigation of fatigue behaviour (LCF/HCF)

- Analysis of creep properties of metals and metal alloys (e.g. solder) under stress for the description of damage accumulation

- Influence of harsh environmental conditions (e.g.moisture) on materials properties

- Determination of thermally induced deformation behaviour (e.g. CTE,Tg) over the range -100°C to 450°C of different materials and components

- Determination of fracture-mechanical properties: Assessment of toughness for the micro/nano range and experimental fracture mechanics at the interface

- Warpage characterization of components and substrates

- Material characterization by in-situ testing methods

If you do not find your need in our list, please contact us. We are happy to develop and validate new techniques for your specific application requirement.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM