Three trends driving the demand for EOCB

- Modern telecommunications needs fast progress in photonic interconnection technology to keep pace with the massive growth of data being transmitted. The effects need to be felt in particular in the data centers that act as the interjections – and often bottlenecks – of this busy traffic system. But even in the field, enormous amounts of data need to be processed and transmitted, e.g. in self-driving cars.

- Many areas of research depend on optical sensor technology, typically using either free beams or fiber-routed light. Both choices, however, suffer from reliability and mechanical stability issues and often only offer low integration density.

- Quantum technology demands that the materials used in many applications need to be far more dimensionally stable and across a far wider temperature range than ever before, that the packaging is hermetically sealed, and that high transparency can be guaranteed across a broad spectrum of wavelengths.

The Solution

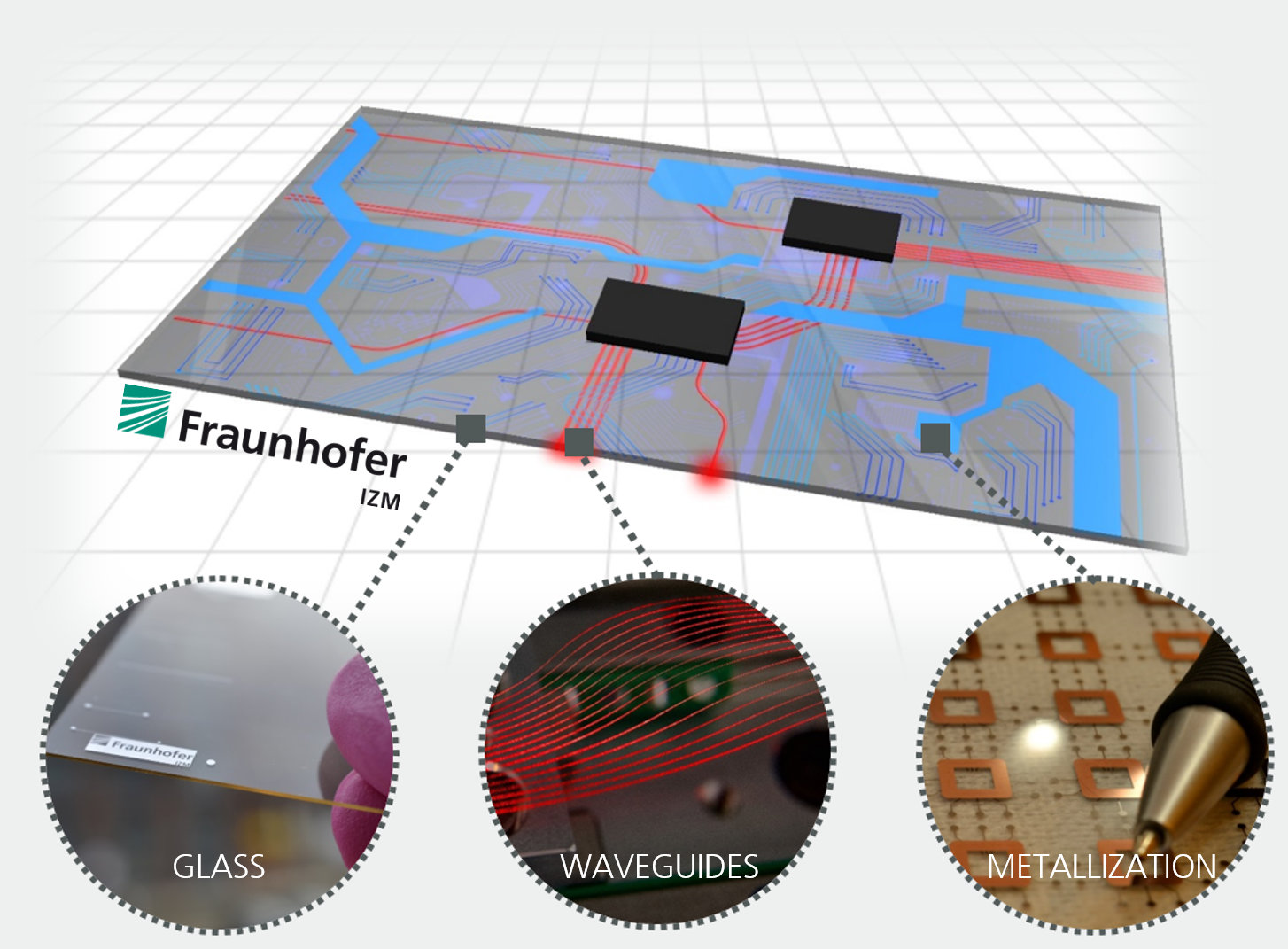

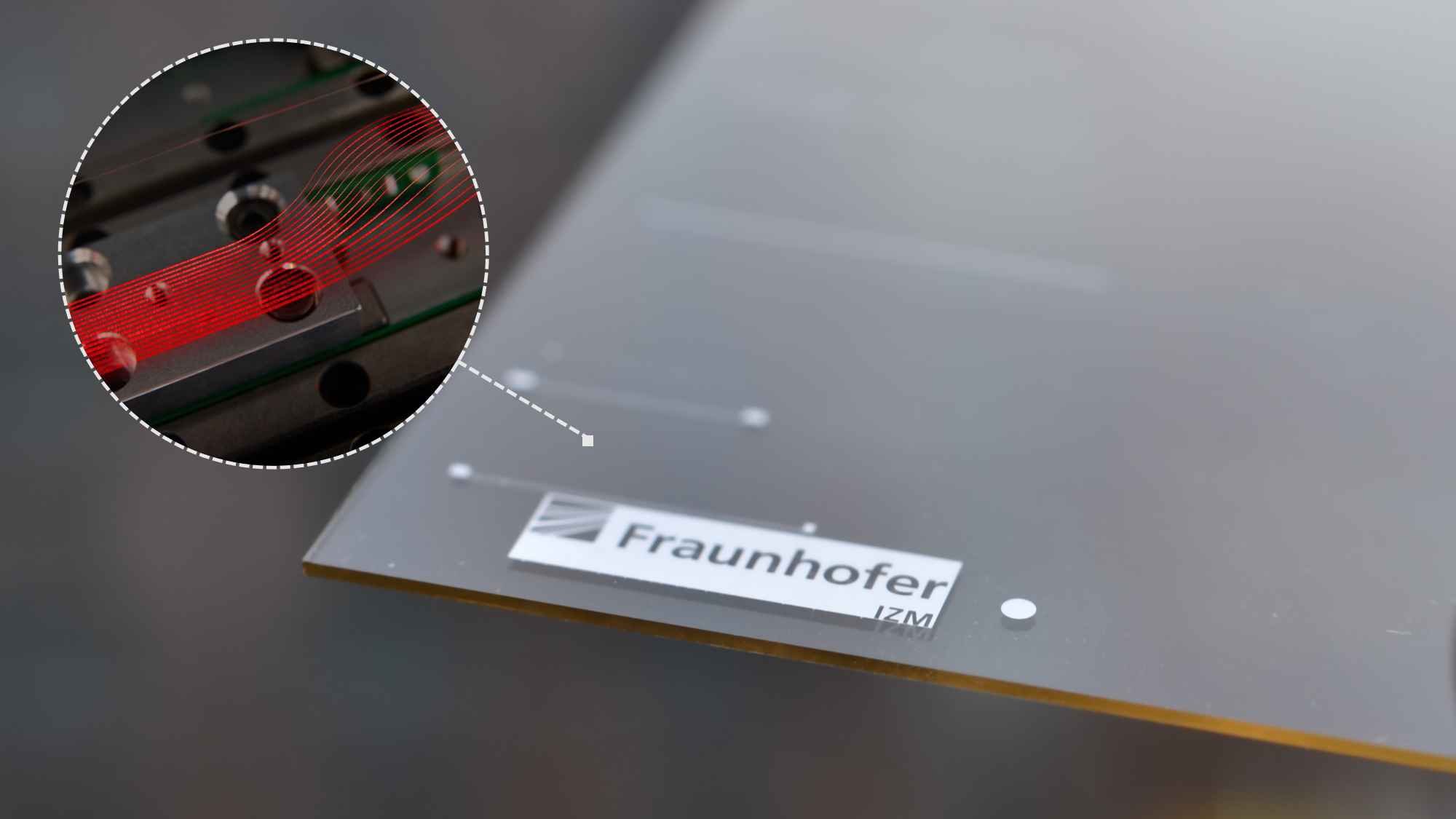

Combining electrical and optical layers in a single circuit board or chip can be a solution to all of these challenges. Fraunhofer IZM produced a first concept of such a combined electro-optical circuit board already in 1999 and has continued to make progress in the field. Since 2003, the necessary optical layer can be produced with commercially available large-format thin glass panels.

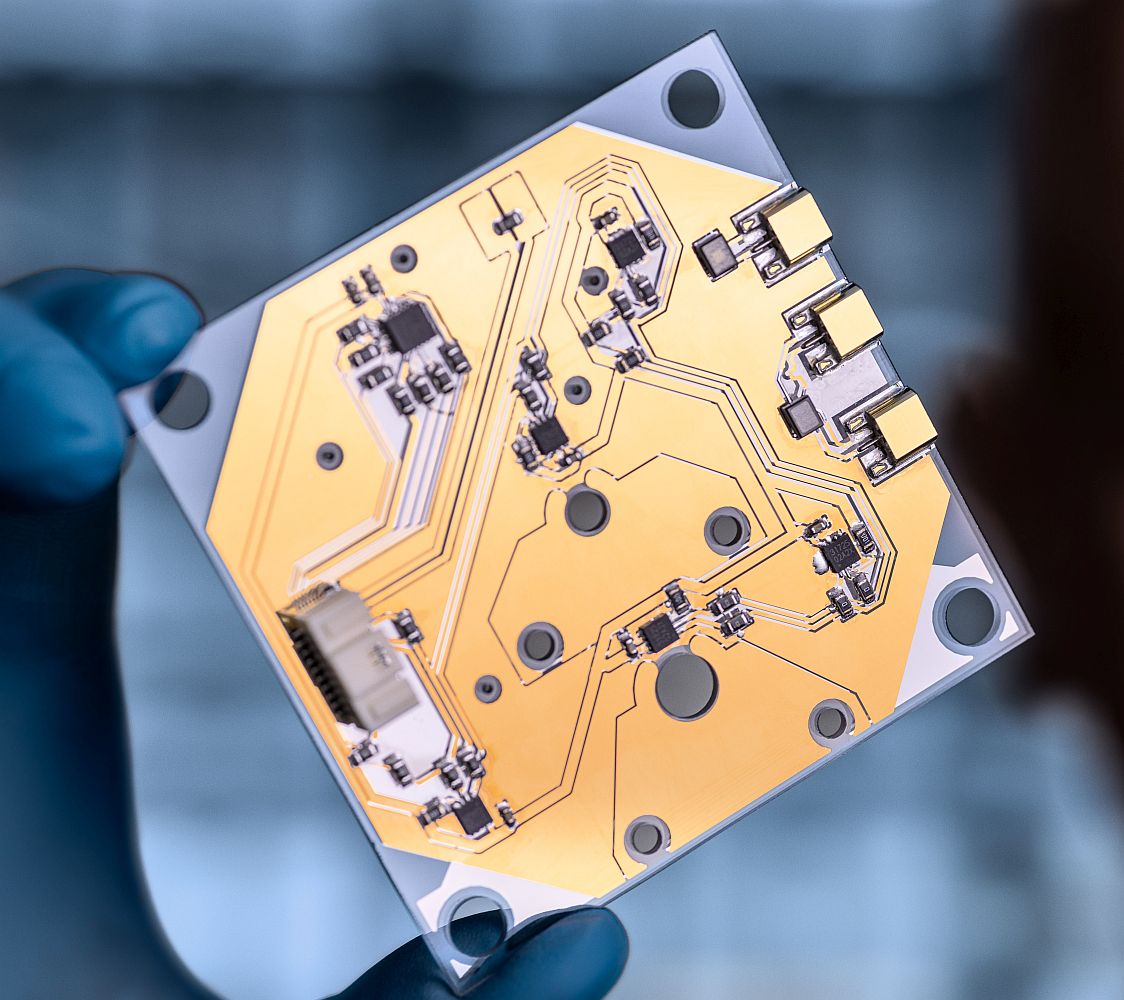

Electro-optical circuit boards or EOCB can realize the immense potential of optical signal transmissions for circuit board and chip design. In telecommunications, the waveguides included in the optical layer can receive the signals from fiber conductors and navigate them to their destinations on the circuit board. This combination of electrical and optical layers is currently receiving considerable attention in concepts like co-packaging. In optical sensor technology, waveguides of this type that let light interact specifically with the analytical targets promise a new level of versatility, as do the excellent properties of glass in terms of biocompatibility or chemical reactivity. Integration into thin glass panels offers better mechanical stability when compared to conventional fibers, and it circumvents the need for complex beamforming or guiding structures to allow for more densely packed designs. In quantum technology applications, a combination of electrical and optical functionality in glass also opens up new avenues for moving optical structures onto the system level.

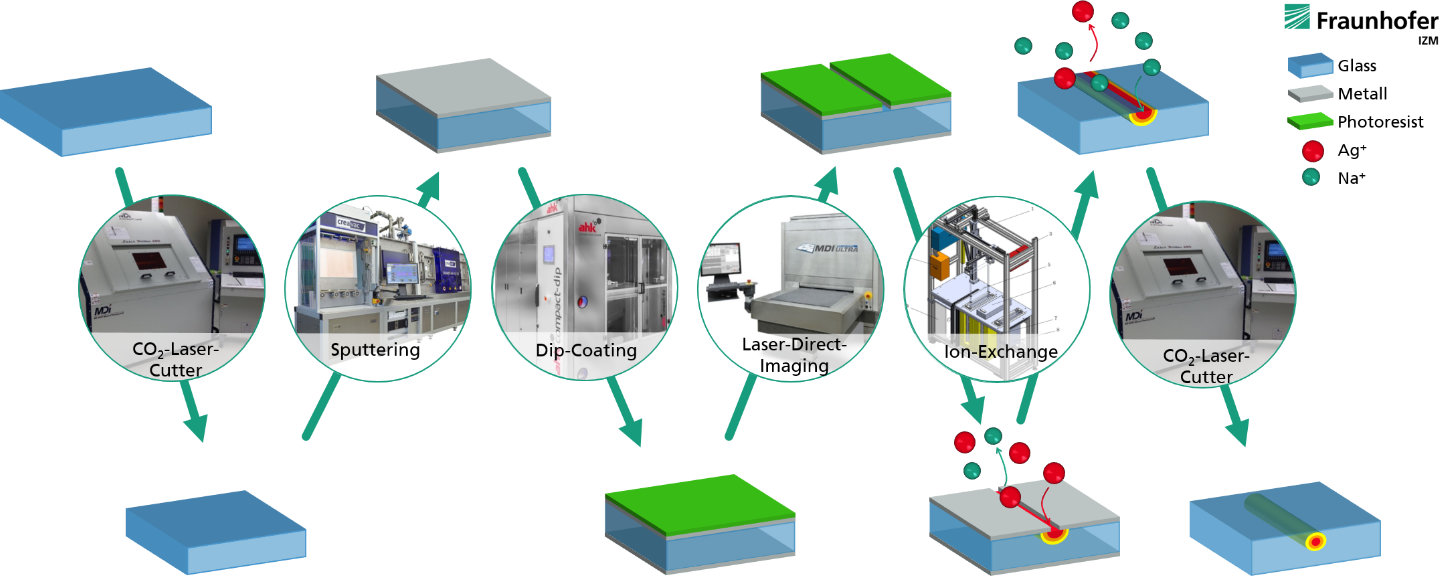

In the past twenty years, Fraunhofer IZM has cooperated closely with research and industry partners to develop a process that can produce electro-optical circuit boards with commercial equipment at the following specifications:

- Board formats up to 18” x 12”

- Board thickness 300 to 700µm

- optical layer

- Graded index waveguides

- Mono and multimodal

- Propagation loss <0.1 dB/cm (@1550nm)

- transparent at 400 to 1600 nm

- electrical layer

- structured metalization layers: Al, Cr, Cu, Ti, WTi

- line space: up to 3µm

- galvanization: Ag, Au, Cu, Ni

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM