Reliability: simulation, test and optimization

Reliability: simulation, test and optimization cover the development and application of experiments and simulations which make it possible to "Design for Reliability". The basis is provided by life-time models determined in accelerated tests.

The combination of simulation and experiments can be used to derive design rules. As a consequence, the reliability of new products can be increased, and therefore, new fields of applications in microsystem technology can then be available.

The following approaches are adopted, further developed and combined:

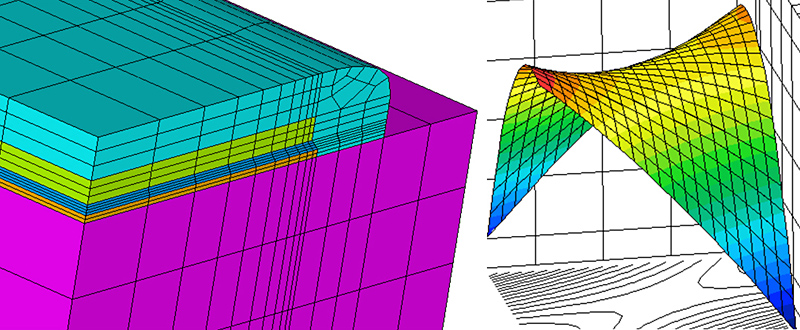

- Multi-physics simulation of fault mechanisms and optimisation at the component and system levels

- Combined and accelerated tests (temperature, moisture and vibration)

- Testability and online-monitoring with accelerated ageing

- Ageing and failure analyses, sample preparation and analysis

Typical mechanisms to be investigated are:

- Thermomechanical fatigue (e.g. soldered connections, through vias)

- Mechanical overloading

- Crack formation and delamination

- Electro-migration

- Moisture diffusion

Achieving solutions requires close cooperation with other groups in IZM and project partners. This will also allow better coordination in order to reach other development goals (e.g. technological feasibility, costs, EMC, thermal management, energy consumption, or environmental impact).

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM