Reliability- evaluation, tests and optimization

Accelerated tests can be used in order to simulate the thermal, climatic and mechanical field stress of electronic assemblies. In combination with FEM- calculation a life-time prediction can be derived. Failure analysis can be used for optimization of material choice and/or technology.

The application area Reliability- Evaluation, tests and optimization focuses on the application specific qualification of new solder alloys and packaging solutions for electronic assemblies on different substrates as well as lifetime prediction based on accelerated testing in combination with FEM- calculation.

All thermal, climatic and mechanical tests are carried out in accordance with DIN EN, IEC, IPC and MIL standards or customer specifications.

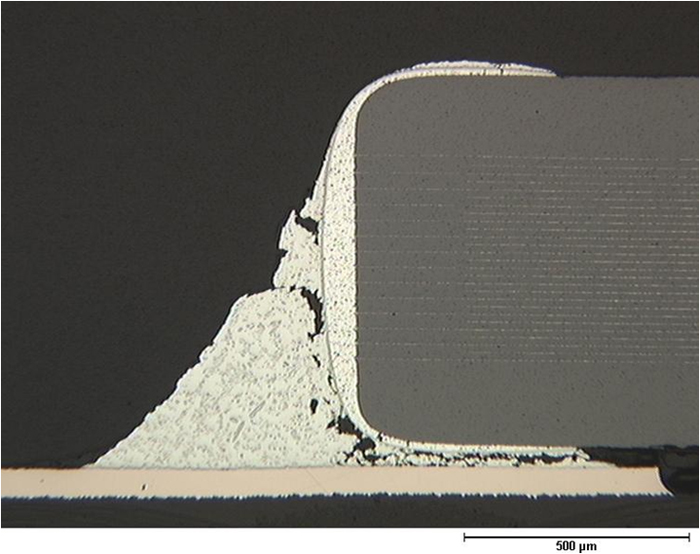

Assembly inspection and failure analysis after testing includes the investigation of structural transformations and intermetallic phase growth as well as crack propagation, using microsectioning or focused-ion-beam preparation(FIB) followed by optical inspection and SEM/EDX analysis.

Based on physics-of-failures optimization of material choice and/or technology can be done.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM