Optoelectronics

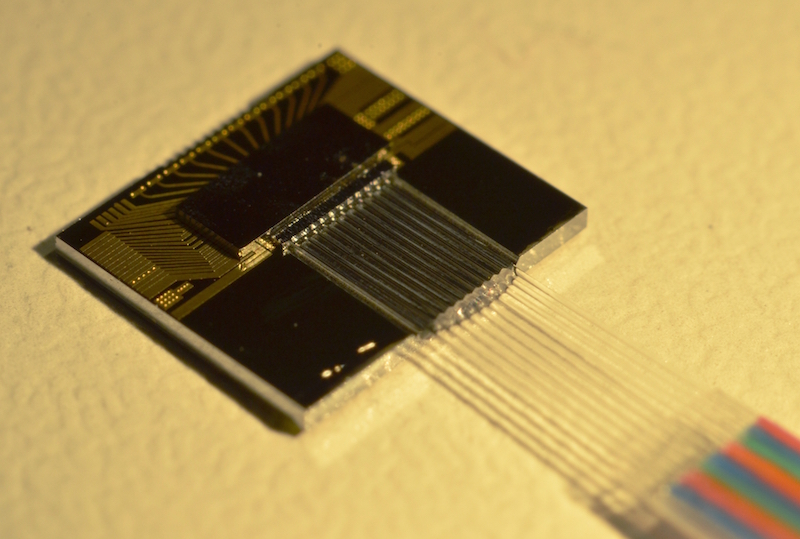

Depending on the field of use optoelectronic components have very different requirements. Datacom lasers und photodiodes need to be single mode compatible and the accuracy of the assembly must be better than one micrometre to fulfil today’s requirements for data rates.

Components for optical measurement systems normally don’t need the high accuracy but the characteristics should be stable under different environmental conditions.

Most requirements for solid state lighting, like high power density, are almost fulfilled, but a wide field of special lighting applications is yet not addressed satisfactory.

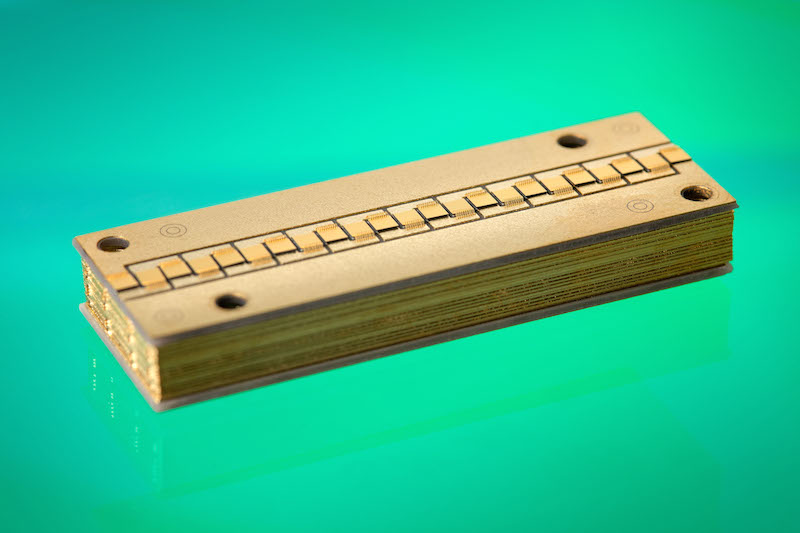

High powers lasers are more cost intensive and have to realize the highest possible power density. To do this the heat has to be transferred into a liquid coolant taking care on all thermal expansion coefficient along the thermal path.

To solve all this different challenges various technologies were developed or improved at IZM (see below). Fluxless soldering with SnAg and AuSn, sintering with and without pressure with silver but also other metals experimentally, thermo compression bonding are some examples. For high accurate assemblies thermode soldering or reflow soldering with self-alignment are suitable technologies. Several small batch ovens are used for process development with specific gases, plasma or mechanical activation. For high volume processes production like inline reflow ovens and vapour phase ovens for condensation soldering are available.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM