2.5/3D Technologies

- TSV Integration

- Silicon interposer TSV first

- TSV via middle

- TSV via last

- Device stack

- Glass interposer and TGV Integration

- 2.5/3D Interposer

- Backside Interconnects

- 3D Stack Formation

- Flexible High Density Multi-Layer Substrates

- Polymeric interposers based on thin film flex technology

High Density Redistribution

- High Density Redistribution

- Multi-layer Redistribution

- Polymers for high-density Interconnects

- Copper/Polymer Evaluation Kit

- Integration of passive devices

- Glass substrate and layers

- Fan-out Wafer-Level Packaging

- High-Density-Routing (RDL)

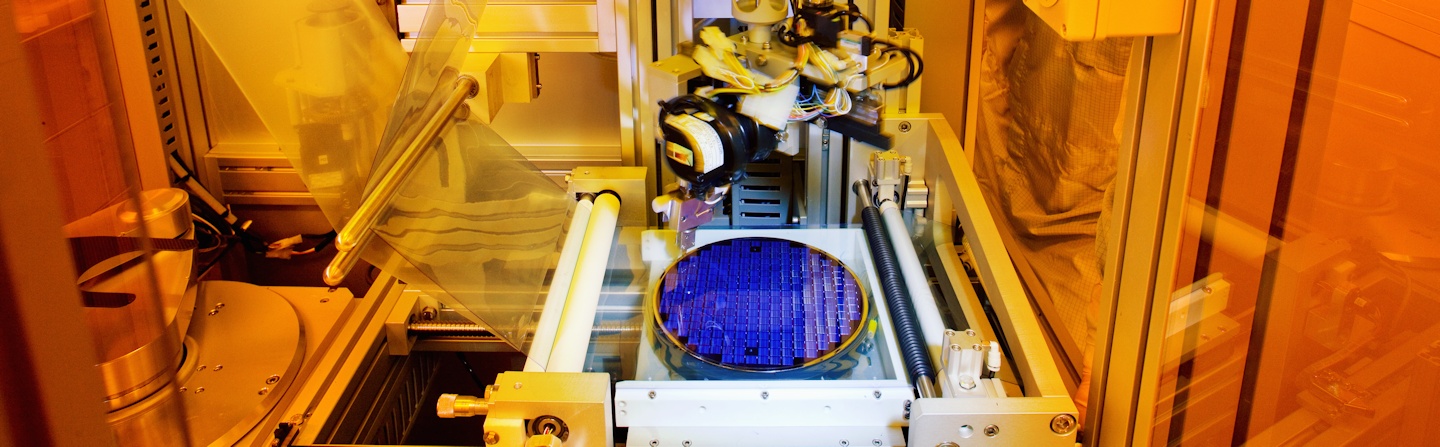

Wafer-Bumping

- Wafer Bumping via Electroplating

- Solder & pillar bumps

- Fine-pitch bumping for Pixel Detectors

- Fabrication of nanoporous old Structures

- Mechanical gold stud bumping

- Single chip bumping

- Electro chemische deposition

Wafer-Bonden

- Permanent wafer-to-wafer bonding

- Temporary wafer bonding for thin wafer handling

- Wafer level capping

Thinning/Singulation/Dicing

- Back grinding tape lamination

- Wafer backgrinding

- Polishing

- mechanical blade dicing

- laser grooving

- laser stealth dicing

- wafer edge trimming

High-Density Assembly

- Fine pitch assembly for pixel detectors

- Detector packaging for medical x-ray imaging and x-ray crystallography

- Interconnect metallurgy and processes

- Thermo compression bonding

- Chip-Stacking

- Fine-pitch flip chip (FC) assembly & die bonding

- Wafer-level solder ball attach (100 – 500 μm)

- Evaluation of low-temperature assembly technologies

- Evaluation of flux free solder connections with self alignment capability

- Reliability investigation of flip chip interconnections

- Chip to Wafer Assembly

Failure Analysis & Reliability Investigation

- Metrology: Bump heights / TSV depth measurement, defect inspection, topology, layer thickness, wafer thickness & bow/ warp (VIS), wafer thickness (infrared), die warpage measurement, physical failure analysis, preparation techniques 3D stack

- FIB / REM imaging

- Copper/polymer evaluation kit - Interdigital finger-type capacitors

Sensor Development

- Sensor design

- Reliability and lifetime optimization

- Standard and customer-specific packaging with integrated sensor data processing e.g. TO8, packages with media separation, molding

- Characterization of pressure (10 m-100 Bar), gas and acceleration sensors (up to 40 g)

- Planar technologies (SiO, SIN deposition, Sputtering)

- Overview sensor activities

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM