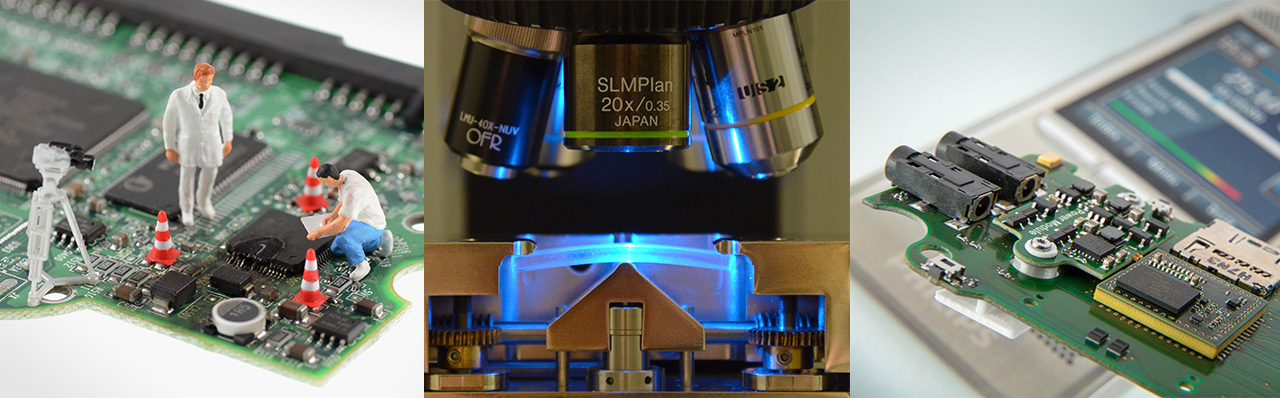

New products and technologies have to comply with an increasing range of strict specifications, and at the same time have to be cost-efficient and environmentally friendly. The Department Environmental and Reliability Engineering supports technological developments until they reach market maturity with environmental and reliability analysis reaching from nano-characterisation level to evaluation and optimisation at the system level. Under the leadership of Dr. Nils F. Nissen, a unique combination is achieved between the established cross-sectional specialist fields of reliability and sustainability.

In view of worldwide extending markets and limited resources, every new generation of products and technologies must generate more functionality and assured reliability while consuming fewer resources. Without adequate reliability, the commercial success of an application is anyway endangered, and at the same time the environmental impact of typically production-intensive microelectronics increases furtherby premature failures or the need for replacements. Sustainable electronic technologies must therefore be reliable and have a low environmental impact.

Fraunhofer Institute for Reliability and Microintegration IZM

Fraunhofer Institute for Reliability and Microintegration IZM